High-Precision Semi Automatic Garment Embossing Machine

Looking to level up your production line? Our high-performance embossing machine is built for precision, durability, and versatility—so you can focus on delivering quality. Whether you’re adding unique textures to fabrics or branding leather products, this machine produces clean, consistent results every time.

- Model name: PT-J6

- Payment Method: L/C at sight or T/T in advance

- Min. Order: 01

- Warranty: 12 Months.

- Packaging: Standard Export Wooden Case

Share:

Request a quote for

High-Precision Semi Automatic Garment Embossing Machine

Looking to level up your production line? Our high-performance embossing machine is built for precision, durability, and versatility—so you can focus on delivering quality. Whether you’re adding unique textures to fabrics or branding leather products, this machine produces clean, consistent results every time.

- Model name: PT-J6

- Payment Method: L/C at sight or T/T in advance

- Min. Order: 01

- Warranty: 12 Months.

- Packaging: Standard Export Wooden Case

Share:

Product Info

Semi Automatic Garment Embossing Machine

Perfect for apparel brands, leather goods makers, and industrial textile printing setups, it’s more than just a heat press machine—it’s a complete solution. Think of it as your go-to garment printing machine, capable of handling a wide range of materials with a fast printing speed to save you time. While an automatic screen printing machine has its place, this technology offers unique, high-value finishes.Product Specification

| Model | PT-K601 | PT-K602 |

| Embossed area(mm) | 300*400 | 400*500 |

| Heating power(kw) | 8.8 | 8.8 |

| Heating method | up and down heating | up and down heating |

| Working station | 2workingstation,4plates | 2workingstation,4plates |

| Power system | Hydraulic,rising speed can be adjusted | Hydraulic,rising speed can be adjusted |

| Pressure | 0-7Mpa, can be adjusted | 0-7Mpa, can be adjusted |

| Total power | 11kw | 11kw |

| Voltage | 380V,50Hz, | 380V,50Hz, |

| Weight(kg) | 650 | 650 |

| Dimension(mm) | 1750*2000*1720 | 1750*2000*1720 |

Advantage & Features

The PJD-J6 embossing machine stands out due to its advanced functionalities. The machine adopts a stable structure for exceptional stability, designed to optimize the garment embellishment process and ensure a good production effect for worry-free use.

- Precision PID Temperature Control: Ensures consistent and accurate heating, vital for perfect embossing printing results. This smart system ensures the plate is heating evenly, preventing fabric damage and maintaining uniformity across the entire working surface.

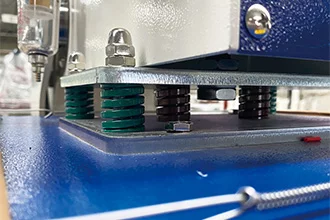

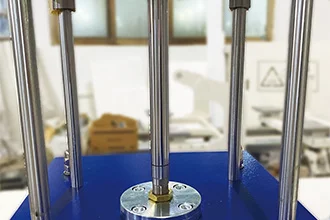

- Robust Hydraulic System: Delivers stable and powerful pressure with a strong compression force, which is crucial for deep and clear embossing on various fabric thicknesses. This uniform pressure helps to prevent product wrinkles and ensures the head runs parallel to the base, guaranteeing consistency.

- Semi-Automatic Operation: Equipped with a PLC touch screen, the PT-J6 offers a labor-saving operation that reduces reliance on manual labor, which in turn helps save labor cost. This highly automated process minimizes errors and boosts overall output, making it an efficient embosser press while ensuring process problems are kept to a minimum. A pneumatic operation design with adjustable air pressure is also available as an accessory.

- High-Quality Components: Built with durable materials and reliable parts to ensure smooth sliding of moving components, ensuring longevity and minimal downtime—a critical factor for manufacturers in Bangladesh.

- Energy Efficiency: Optimized heating and hydraulic systems contribute to lower energy consumption compared to conventional embossing equipment. This aligns with the garment industry’s increasing focus on sustainable practices.

- Safety Features: Integrated emergency stop buttons and overload protection enhance operator safety, a paramount concern in any industrial setting.

Applications

Our embossing machine is a versatile tool for garment manufacturers, offering both decorative and functional enhancements.

- Brand Logos & Labels: Use the embossing printer to create raised brand marks directly on garments—boosting identity and helping prevent counterfeits.

- 3D Textile Designs: Add stylish textures to t-shirts, hoodies, and denim with our embosser press, giving garments a premium look and feel.

- Sportswear Embellishment: Perfect for embossing patterns on jerseys and activewear—both decorative and non-slip.

- Premium Apparel Detailing: Elevate luxury fashion pieces using our garment printing machine to apply clean, embossed details.

- Functional Finishes: Apply grip-like textures using the embossing press for added functionality on select textile items.

- Wide Fabric Compatibility: Works with cotton, polyester, blends, nylon, and more—ideal for diverse production lines, including tees and shirts that would typically be decorated using a screen frame for screen printing.

Specification

Semi Automatic Garment Embossing Machine

Perfect for apparel brands, leather goods makers, and industrial textile printing setups, it’s more than just a heat press machine—it’s a complete solution. Think of it as your go-to garment printing machine, capable of handling a wide range of materials with a fast printing speed to save you time. While an automatic screen printing machine has its place, this technology offers unique, high-value finishes.Product Specification

| Model | PT-K601 | PT-K602 |

| Embossed area(mm) | 300*400 | 400*500 |

| Heating power(kw) | 8.8 | 8.8 |

| Heating method | up and down heating | up and down heating |

| Working station | 2workingstation,4plates | 2workingstation,4plates |

| Power system | Hydraulic,rising speed can be adjusted | Hydraulic,rising speed can be adjusted |

| Pressure | 0-7Mpa, can be adjusted | 0-7Mpa, can be adjusted |

| Total power | 11kw | 11kw |

| Voltage | 380V,50Hz, | 380V,50Hz, |

| Weight(kg) | 650 | 650 |

| Dimension(mm) | 1750*2000*1720 | 1750*2000*1720 |

Advantage & Features

Advantage & Features

The PJD-J6 embossing machine stands out due to its advanced functionalities. The machine adopts a stable structure for exceptional stability, designed to optimize the garment embellishment process and ensure a good production effect for worry-free use.

- Precision PID Temperature Control: Ensures consistent and accurate heating, vital for perfect embossing printing results. This smart system ensures the plate is heating evenly, preventing fabric damage and maintaining uniformity across the entire working surface.

- Robust Hydraulic System: Delivers stable and powerful pressure with a strong compression force, which is crucial for deep and clear embossing on various fabric thicknesses. This uniform pressure helps to prevent product wrinkles and ensures the head runs parallel to the base, guaranteeing consistency.

- Semi-Automatic Operation: Equipped with a PLC touch screen, the PT-J6 offers a labor-saving operation that reduces reliance on manual labor, which in turn helps save labor cost. This highly automated process minimizes errors and boosts overall output, making it an efficient embosser press while ensuring process problems are kept to a minimum. A pneumatic operation design with adjustable air pressure is also available as an accessory.

- High-Quality Components: Built with durable materials and reliable parts to ensure smooth sliding of moving components, ensuring longevity and minimal downtime—a critical factor for manufacturers in Bangladesh.

- Energy Efficiency: Optimized heating and hydraulic systems contribute to lower energy consumption compared to conventional embossing equipment. This aligns with the garment industry’s increasing focus on sustainable practices.

- Safety Features: Integrated emergency stop buttons and overload protection enhance operator safety, a paramount concern in any industrial setting.

Applications

Applications

Our embossing machine is a versatile tool for garment manufacturers, offering both decorative and functional enhancements.

- Brand Logos & Labels: Use the embossing printer to create raised brand marks directly on garments—boosting identity and helping prevent counterfeits.

- 3D Textile Designs: Add stylish textures to t-shirts, hoodies, and denim with our embosser press, giving garments a premium look and feel.

- Sportswear Embellishment: Perfect for embossing patterns on jerseys and activewear—both decorative and non-slip.

- Premium Apparel Detailing: Elevate luxury fashion pieces using our garment printing machine to apply clean, embossed details.

- Functional Finishes: Apply grip-like textures using the embossing press for added functionality on select textile items.

- Wide Fabric Compatibility: Works with cotton, polyester, blends, nylon, and more—ideal for diverse production lines, including tees and shirts that would typically be decorated using a screen frame for screen printing.

Product Comparison

Comparison Table: PT-J6 vs. Similar Products

| Feature / Model | PT-J6 Automatic Garment Embossing Machine | Semi-Automatic Embossing Machine (e.g., Jinyu) | Manual Heat Press (with embossing dies) |

| Automation Level | Fully Automatic (PLC controlled) | Semi-Automatic (some manual intervention) | Fully Manual |

| Production Capacity | High-volume, Continuous Production | Medium-volume, Batch-based | Low-volume, Individual Piece Work |

| Pressure Control | Precise Hydraulic, Consistent Pressure | Hydraulic/Pneumatic, Variable Consistency | Operator Dependent, Less Consistent |

| Temperature Control | PID, Highly Accurate and Stable | Analog/Digital, Moderate Accuracy | Basic Thermostat, Less Stable |

| Consistency of Output | Excellent, High Uniformity | Good, but can vary with operator skill | Variable, Prone to inconsistencies |

| Labor Requirement | Minimal operator interaction | Requires attentive operator | Highly labor-intensive |

| Energy Efficiency | Optimized heating and hydraulic systems | Generally lower efficiency | Basic, less optimized |

| Ideal For | Large-scale production, Premium garments | Medium-sized businesses, Diverse orders | Small businesses, Custom one-offs |

| Investment | Higher initial investment | Moderate initial investment | Lower initial investment |

Warranty and Technical Support

Warranty Period: 12 Months.

Warranty Terms: The Garment Embossing Machine is supported by service warranty that applies to its primary electrical components, hydraulic or pneumatic system, and digital control units. Due to regular operational wear, parts such as heating plates, rubber pads, and sealing elements are classified as consumables and are not included under warranty coverage. Should any of the eligible components experience failure, our technical team will perform repair or replacement services, though customers must purchase any required spare parts independently. All shipping costs for sending or receiving parts and equipment remain the responsibility of the customer.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Product Warranty

Warranty and Technical Support

Warranty Period: 12 Months.

Warranty Terms: The Garment Embossing Machine is supported by service warranty that applies to its primary electrical components, hydraulic or pneumatic system, and digital control units. Due to regular operational wear, parts such as heating plates, rubber pads, and sealing elements are classified as consumables and are not included under warranty coverage. Should any of the eligible components experience failure, our technical team will perform repair or replacement services, though customers must purchase any required spare parts independently. All shipping costs for sending or receiving parts and equipment remain the responsibility of the customer.

Technical & After Sales Service

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

Delivery

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Company Info

Company Information

Address: House #9, Block #A, Road #1, Niketon, Dhaka-1212, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries.

With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.

Q1: What materials can this garment embossing machine work on?

It works great on fabric, leather, paper, PVC, and other similar materials.

Q2: Is this machine automatic or manual?

It’s a semi-automatic/automatic machine with digital touch controls—very easy to use.

Q3: Can I use it for garment labels?

Yes! It’s perfect for garment labeling, leather tags, and even custom logos.

Q4: Does it come with a warranty?

Yes, we offer a 1-year warranty covering manufacturing defects.

Q6: Is training or setup support provided?

Yes. We include guides, video tutorials, and remote help if needed.

Q8: What’s included in the box?

You’ll get the machine, power cable, manual, and a starter toolkit.

Q9: Is it hard to maintain?

Not at all. It’s built to last and designed for low maintenance.