Roller Heat Transfer Press Machine for Sublimation Printing on Fabric & Garments

The PT-J9 Heat Roller Transfer Machine is an industrial-grade, oil-heated, roll-to-roll heat press designed for high-volume sublimation and heat transfer printing.

- Model name: PT-J9

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months

- Packaging: Standard Export Wooden Case

Share:

Request a quote for

Roller Heat Transfer Press Machine for Sublimation Printing on Fabric & Garments

The PT-J9 Heat Roller Transfer Machine is an industrial-grade, oil-heated, roll-to-roll heat press designed for high-volume sublimation and heat transfer printing.

- Model name: PT-J9

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months

- Packaging: Standard Export Wooden Case

Share:

Product Info

Heat Roller Transfer Machine

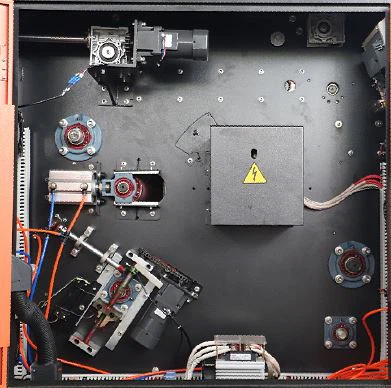

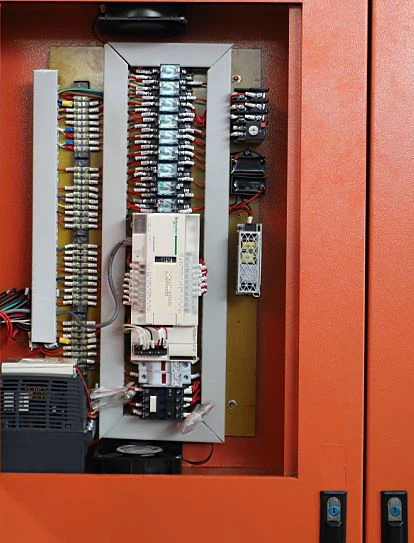

Featuring a large drum diameter and precise PLC control, this machine ensures consistent temperature distribution and exceptional transfer quality for textiles, sportswear, and promotional materials, making it an ideal heat press machine for demanding production environments in Bangladesh.Product Specification

| Model | PT-J901 | PT-J902 | PT-J903 | PT-J904 |

| Power Configuration | Single-phase two-wire 220V/50HZ | Three-phase four-wire 380V/50HZ | Three-phase four-wire 380V/50HZ | Three-phase four-wire 380V/50HZ |

| Power | 7KW | 20KW | 43KW | 60KW |

| Heating | Oil-base heating pipe | Oil-base heating pipe | Oil-base heating pipe | Oil-base heating pipe |

| Drum Diameter | 200mm | 420mm | 600mm | 800mm |

| Blanket width | 1150mm | 17330mm | 17330mm | 1960mm |

| Working Table area | 1000*1289 | 1510*1780 | 3000*1780 | 3000*2000 |

| Max working speed | 60-80m/h | 100-120m/h | 210-230m/h | 300-400m/h |

| Packing size | 1800*750*1200mm | 2640*1400*1200mm | 2640*1540*1570mm | 3100*1800*1800mm |

| Net weight | 320kG | 1500kG | 2500kG | 3500kG |

Advantage & Features

- The rollers are precisely lathed and ground to ensure uniform thickness, maintaining a temperature variation of just ±1°C. The surface is coated with Teflon to prevent sticking and keep the fabric from clinging to the roller.

- Imported stainless steel heating pipes from Taiwan are fully immersed in thermal oil, allowing for faster heating and up to 15% energy savings.

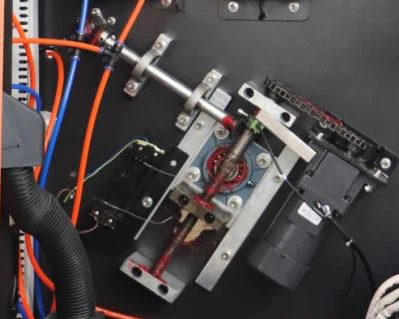

- The pneumatic compression system lets you adjust pressure based on the material, resulting in quicker transfer and more vibrant colors.

- An inflatable shaft keeps fabric and paper tightly wound and aligned, reducing manual work and improving efficiency.

- A synchronous rod and pressure balance bar help maintain even pressure across the roller, prevent blanket cooling during shutdowns or power outages, and extend blanket life.

- An independent oil tank makes it easy to add conduction oil and offers added safety with explosion-proof design.

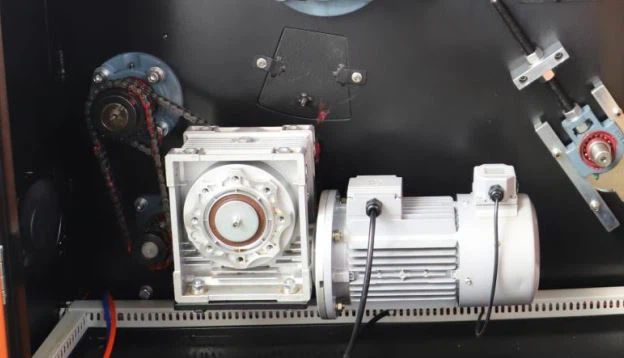

- The frequency converter allows smooth adjustment of printing speed on the roller heat transfer machine, keeping the transfer process stable and consistent.

- Supports three inputs—fabric, transfer paper, and protective paper—and two outputs for collecting used paper, making it ideal for printing on rolls, cut pieces, and finished garments.

Applications

The versatility and efficiency of the PT-J9 Heat Roller Transfer Machine make it indispensable across various industries, particularly thriving within Bangladesh’s key sectors:

- Textile and Garment Manufacturing: This is the primary application, especially for dye-sublimation printing on polyester and polyester-blend fabrics. It’s used for:

- Sportswear & Activewear: Uniforms, jerseys, leggings, and athletic apparel requiring vibrant, durable, full-color designs.

- Fashion Apparel: Creating unique patterns, intricate designs, and custom prints on garments.

- Home Textiles: Production of customized curtains, bedding, upholstery fabrics, and decorative items.

- Soft Signage and Banners: Producing large-format, eye-catching fabric banners, flags, and display graphics for events, advertising, and retail environments. The continuous feeding capability of the heat roller transfer machine is perfect for this.

- Promotional Merchandise: Sublimating designs onto various polyester-coated promotional items like custom bags, lanyards, and certain types of caps.

- Industrial Fabrics: Transferring functional coatings or designs onto specialized industrial textiles where consistent heat and pressure are required.

The ability of this heat press machine to handle roll-to-roll printing makes it highly efficient for mass production, a critical factor for the export-oriented textile industry in Bangladesh.

Specification

Heat Roller Transfer Machine

Featuring a large drum diameter and precise PLC control, this machine ensures consistent temperature distribution and exceptional transfer quality for textiles, sportswear, and promotional materials, making it an ideal heat press machine for demanding production environments in Bangladesh.Product Specification

| Model | PT-J901 | PT-J902 | PT-J903 | PT-J904 |

| Power Configuration | Single-phase two-wire 220V/50HZ | Three-phase four-wire 380V/50HZ | Three-phase four-wire 380V/50HZ | Three-phase four-wire 380V/50HZ |

| Power | 7KW | 20KW | 43KW | 60KW |

| Heating | Oil-base heating pipe | Oil-base heating pipe | Oil-base heating pipe | Oil-base heating pipe |

| Drum Diameter | 200mm | 420mm | 600mm | 800mm |

| Blanket width | 1150mm | 17330mm | 17330mm | 1960mm |

| Working Table area | 1000*1289 | 1510*1780 | 3000*1780 | 3000*2000 |

| Max working speed | 60-80m/h | 100-120m/h | 210-230m/h | 300-400m/h |

| Packing size | 1800*750*1200mm | 2640*1400*1200mm | 2640*1540*1570mm | 3100*1800*1800mm |

| Net weight | 320kG | 1500kG | 2500kG | 3500kG |

Advantage & Features

Advantage & Features

- The rollers are precisely lathed and ground to ensure uniform thickness, maintaining a temperature variation of just ±1°C. The surface is coated with Teflon to prevent sticking and keep the fabric from clinging to the roller.

- Imported stainless steel heating pipes from Taiwan are fully immersed in thermal oil, allowing for faster heating and up to 15% energy savings.

- The pneumatic compression system lets you adjust pressure based on the material, resulting in quicker transfer and more vibrant colors.

- An inflatable shaft keeps fabric and paper tightly wound and aligned, reducing manual work and improving efficiency.

- A synchronous rod and pressure balance bar help maintain even pressure across the roller, prevent blanket cooling during shutdowns or power outages, and extend blanket life.

- An independent oil tank makes it easy to add conduction oil and offers added safety with explosion-proof design.

- The frequency converter allows smooth adjustment of printing speed on the roller heat transfer machine, keeping the transfer process stable and consistent.

- Supports three inputs—fabric, transfer paper, and protective paper—and two outputs for collecting used paper, making it ideal for printing on rolls, cut pieces, and finished garments.

Applications

Applications

The versatility and efficiency of the PT-J9 Heat Roller Transfer Machine make it indispensable across various industries, particularly thriving within Bangladesh’s key sectors:

- Textile and Garment Manufacturing: This is the primary application, especially for dye-sublimation printing on polyester and polyester-blend fabrics. It’s used for:

- Sportswear & Activewear: Uniforms, jerseys, leggings, and athletic apparel requiring vibrant, durable, full-color designs.

- Fashion Apparel: Creating unique patterns, intricate designs, and custom prints on garments.

- Home Textiles: Production of customized curtains, bedding, upholstery fabrics, and decorative items.

- Soft Signage and Banners: Producing large-format, eye-catching fabric banners, flags, and display graphics for events, advertising, and retail environments. The continuous feeding capability of the heat roller transfer machine is perfect for this.

- Promotional Merchandise: Sublimating designs onto various polyester-coated promotional items like custom bags, lanyards, and certain types of caps.

- Industrial Fabrics: Transferring functional coatings or designs onto specialized industrial textiles where consistent heat and pressure are required.

The ability of this heat press machine to handle roll-to-roll printing makes it highly efficient for mass production, a critical factor for the export-oriented textile industry in Bangladesh.

Product Comparison

Product Comparison Table with Similar Products

| Feature | PT-J9 Heat Roller Transfer Machine (Typical) | UniPrint UP-HT1700 | HB Heat Press Calendar (MTX Series) |

| Roller Diameter | 420-600mm | 420mm | 200mm – 250mm |

| Working Width | 1700-1800mm | 1700mm | 1180mm – 1730mm |

| Heating Method | Oil-based heating | Oil-based heating | Oil-based heating |

| Control System | PLC Control | Digital Control | Digital Control |

| Rated Power (KW) | 11-30 KW | 30 KW | 6 KW – 11 KW |

| Max. Speed | 100-120 m/hr | 0-8 m/min | 0-1200 mm/min |

| Auto Features | Auto Blanket Alignment, Cooling | Pneumatic Pressure | Auto Cool Down, Spring Loaded Take-ups |

| Typical Use Case | High-volume textile sublimation | Roll-to-roll & Cut-piece sublimation | Dye sub banners, soft signage, sportswear |

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The PT-J9 Heat Roller Transfer Machine comes with a service warranty that covers its main electrical components, roller heating system, and control unit. Some items—like heat-resistant belts, silicone rollers, and pressure seals—naturally wear out over time and are considered consumables, so they aren’t covered under the warranty. If any covered part stops working during the warranty period, our technicians will handle the repair or replacement, but customers will need to purchase any necessary spare parts. Please note that customers are responsible for all shipping costs when sending or receiving parts or equipment.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Product Warranty

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The PT-J9 Heat Roller Transfer Machine comes with a service warranty that covers its main electrical components, roller heating system, and control unit. Some items—like heat-resistant belts, silicone rollers, and pressure seals—naturally wear out over time and are considered consumables, so they aren’t covered under the warranty. If any covered part stops working during the warranty period, our technicians will handle the repair or replacement, but customers will need to purchase any necessary spare parts. Please note that customers are responsible for all shipping costs when sending or receiving parts or equipment.

Technical & After Sales Service

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Company Info

Prominent Tec Company Information

Address: House #9, Block #A, Road #1, Niketon, Dhaka-1212, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.

Q1: What type of printing can the PT-J9 Heat Roller Transfer Machine perform?

A1: It performs dye-sublimation and heat transfer printing on polyester, blends, and coated surfaces like ceramics or metals.

Q2: Is this machine suitable for small businesses or industrial-scale production?

A2: It’s industrial-grade and ideal for high-volume production, best suited for established businesses in Bangladesh that use heat transfer machines.

Q3: How does the oil-based heating system benefit the transfer process?

A3: It provides even heat, prevents cold spots, ensures uniform color transfer, and improves print quality.

Q4: What kind of maintenance does a heat roller transfer machine require?

A4: Clean rollers and blanket regularly, check pressure, temperature, oil levels, and schedule occasional servicing.

Q5: Can this heat press machine handle different fabric widths?

A5: Yes, it handles up to 1700–1800mm wide fabrics and can process narrower ones with proper alignment.