High-Precision Cardboard to Cardboard Laminator | Industrial Lamination Machine

Transform your packaging production with our industrial-grade Cardboard to Cardboard Laminator, engineered specifically for high-volume manufacturing. Designed to handle the unique challenges of the Bangladesh market, this fully automatic Cardboard Laminator features advanced Lead Edge Feeding technology to process warped boards with zero jamming.

- Model name: FKT-DX1207

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months.

- Packaging: Standard Export Wooden Case

Share:

Request a quote for

High-Precision Cardboard to Cardboard Laminator | Industrial Lamination Machine

Transform your packaging production with our industrial-grade Cardboard to Cardboard Laminator, engineered specifically for high-volume manufacturing. Designed to handle the unique challenges of the Bangladesh market, this fully automatic Cardboard Laminator features advanced Lead Edge Feeding technology to process warped boards with zero jamming.

- Model name: FKT-DX1207

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months.

- Packaging: Standard Export Wooden Case

Share:

Product Info

Cardboard to Cardboard Laminator

With speeds up to 16,000 sheets per hour and precision servo control, this Cardboard to Cardboard Laminator delivers export-quality litho-laminated cartons while cutting glue consumption by up to 30%.Product Specification

| S/L | Source Feature/Finding | Customer Requirement |

| 01 | Max. Sheet Size(mm): 1200Wx720L Min. Sheet Size(mm): 450Wx450L Thickness of Upper Paper: 100-800g/m² Thickness of Bottom Paper: 180-1800g/m² Max. Speed: 150pcs/min (Subject to Paper Quality) Laminating Precision: ±0.5mm(Standard smooth paperboard) Total Weight: 7000kg Total Length: 8900mm Operation Space: 3M×12M Power: AC380V/50Hz/16kW | Flute Laminator |

Advantage & Features

Aligning System:

- Advanced dynamic alignment synchronized with the laminating process.

- Equipped with a front stopper and side stopper to ensure accurate lamination.

- Capable of laminating two paperboards with ±0.5mm precision or better when using quality materials.

Transmission System:

- A cutting-edge planetary transmission design ensures balanced power distribution.

- The entire machine uses timing belt transmission—maintenance-free, low-noise, and highly efficient.

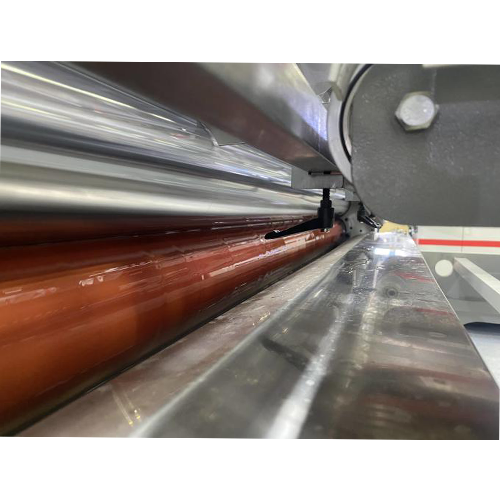

Pressing Conveyor:

- Motorized control of rotation speed and pressing length makes paper size changes simple.

- Supports multi-layer pressing and increases rotation speed by pressing each sheet individually.

- Additional rollers apply strong repeated pressure for smoother, higher-quality finished sheets.

Electric Control System:

- Features three interface components: HMI (Human-Machine Interface), voice alarm, and PLC indicator lights.

- Automatically monitors operating status, detects abnormalities, and records maintenance and working logs.

Applications

This Cardboard to Cardboard Laminator is versatile and essential for various industrial packaging sectors:

- RMG Export Cartons: Producing high-strength, litho-laminated boxes that meet global buyer standards.

- Consumer Electronics: Large format lamination for home appliance packaging (TVs, blenders).

- Luxury Packaging: High-precision lamination for mobile phone boxes and cosmetics where print alignment is critical.

- Food & Agro Packaging: Creating sturdy, hygienic boxes compliant with food safety regulations.

Specification

Cardboard to Cardboard Laminator

With speeds up to 16,000 sheets per hour and precision servo control, this Cardboard to Cardboard Laminator delivers export-quality litho-laminated cartons while cutting glue consumption by up to 30%.Product Specification

| S/L | Source Feature/Finding | Customer Requirement |

| 01 | Max. Sheet Size(mm): 1200Wx720L Min. Sheet Size(mm): 450Wx450L Thickness of Upper Paper: 100-800g/m² Thickness of Bottom Paper: 180-1800g/m² Max. Speed: 150pcs/min (Subject to Paper Quality) Laminating Precision: ±0.5mm(Standard smooth paperboard) Total Weight: 7000kg Total Length: 8900mm Operation Space: 3M×12M Power: AC380V/50Hz/16kW | Flute Laminator |

Advantage & Features

Advantage & Features

Aligning System:

- Advanced dynamic alignment synchronized with the laminating process.

- Equipped with a front stopper and side stopper to ensure accurate lamination.

- Capable of laminating two paperboards with ±0.5mm precision or better when using quality materials.

Transmission System:

- A cutting-edge planetary transmission design ensures balanced power distribution.

- The entire machine uses timing belt transmission—maintenance-free, low-noise, and highly efficient.

Pressing Conveyor:

- Motorized control of rotation speed and pressing length makes paper size changes simple.

- Supports multi-layer pressing and increases rotation speed by pressing each sheet individually.

- Additional rollers apply strong repeated pressure for smoother, higher-quality finished sheets.

Electric Control System:

- Features three interface components: HMI (Human-Machine Interface), voice alarm, and PLC indicator lights.

- Automatically monitors operating status, detects abnormalities, and records maintenance and working logs.

Applications

Applications

This Cardboard to Cardboard Laminator is versatile and essential for various industrial packaging sectors:

- RMG Export Cartons: Producing high-strength, litho-laminated boxes that meet global buyer standards.

- Consumer Electronics: Large format lamination for home appliance packaging (TVs, blenders).

- Luxury Packaging: High-precision lamination for mobile phone boxes and cosmetics where print alignment is critical.

- Food & Agro Packaging: Creating sturdy, hygienic boxes compliant with food safety regulations.

Product Comparison

Product Comparison Table with Similar Products

| Feature | Manual System | Semi-Automatic Machine | Our Automatic Cardboard to Cardboard Laminator |

| Throughput Speed | 300 – 800 sheets/hr | 2,000 – 4,000 sheets/hr | 12,000 – 16,000 sheets/hr |

| Labor Required | High (3-5 persons) | Moderate (2 persons) | Low (1 Operator + Helper) |

| Registration Accuracy | Variable (> ±2mm) | ±1.5mm | ±0.5mm to ±1.0mm |

| Glue Consumption | High (Brush/Manual) | Moderate (Roller) | Low (Precision Anilox) |

| Warped Board Handling | Difficult | Moderate | Excellent (Lead Edge Feeder) |

| Suitable For | Micro-batches | Short Runs / SME | Large Scale / Export Quality |

Warranty Period: 12 Months.

Warranty Terms: The FKT-DX1207 Cardboard to Cardboard Laminator comes with a service warranty that covers technical malfunctions and performance issues related to the machine’s core laminating and sheet alignment functions. Certain components—such as rollers, belts, gears, and other consumable parts—are subject to natural wear and tear and are therefore not covered under this warranty. If any covered part experiences a malfunction within the warranty period, our trained technicians will provide the necessary repair or replacement service. However, customers will be responsible for purchasing any required spare parts. Please note that all shipping and transportation costs associated with sending or receiving parts or equipment remain the responsibility of the customer.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The FKT-DX1207 Cardboard to Cardboard Laminator comes with a service warranty that covers technical malfunctions and performance issues related to the machine’s core laminating and sheet alignment functions. Certain components—such as rollers, belts, gears, and other consumable parts—are subject to natural wear and tear and are therefore not covered under this warranty. If any covered part experiences a malfunction within the warranty period, our trained technicians will provide the necessary repair or replacement service. However, customers will be responsible for purchasing any required spare parts. Please note that all shipping and transportation costs associated with sending or receiving parts or equipment remain the responsibility of the customer.

Technical & After Sales Service

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Company Info

Prominent Tec Company Information

Address: House #9, Block #A, Road #1, Niketon, Dhaka-1212, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.

Q: Can this Cardboard to Cardboard Laminator handle warped corrugated boards?

A: Yes. Its Lead Edge Feeder is designed to grip and feed warped sheets, common in humid climates.

Q: What is the power requirement?

A: Connected load is 16–26 kW. A voltage stabilizer (AVR) is recommended to protect servo motors and the PLC.

Q: How does this machine save glue?

A: Precision anilox rollers reduce usage to 20–25 gsm, saving over 1,500 kg/month for 100,000 sqm output.

Q: Is the machine difficult to maintain?

A: No, but daily roller washing and monthly lubrication are required. Training is provided for PLC and adjustments.

Q: What is the ROI period?

A: Most factories achieve break-even in 18–24 months through labor and glue savings.