High-Speed Roll to Sheet Paper Cutting Machine Automatic Precision Cutter for Paper & Board

Meet the FKT-SCS1400 Paper Cutting Machine, a high-speed automatic paper cutting machine designed to eliminate production bottlenecks in Bangladesh’s demanding print and packaging industries.

- Model name: FKT-SCS1400

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months.

- Packaging: Standard Export Wooden Case

Share:

Request a quote for

High-Speed Roll to Sheet Paper Cutting Machine Automatic Precision Cutter for Paper & Board

Meet the FKT-SCS1400 Paper Cutting Machine, a high-speed automatic paper cutting machine designed to eliminate production bottlenecks in Bangladesh’s demanding print and packaging industries.

- Model name: FKT-SCS1400

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months.

- Packaging: Standard Export Wooden Case

Share:

Product Info

Paper Cutting Machine (Roll to Sheet)

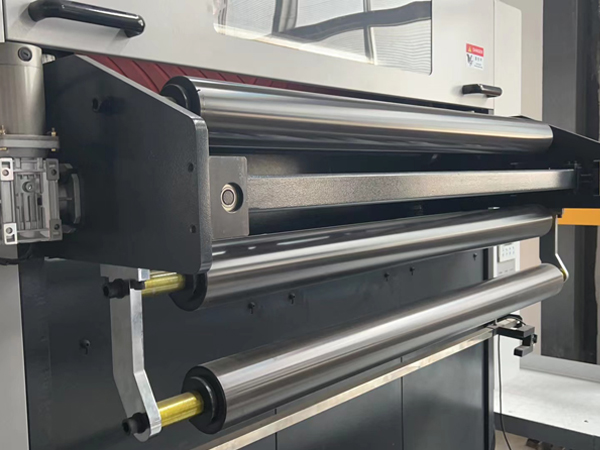

This digital paper cutting machine converts jumbo paper rolls into perfectly cut, press-ready sheets with unmatched precision. Offering a strategic 60-550 GSM versatility, this is the ultimate paper cutting machine for high-volume paper mills, printers, and packaging converters looking to maximize throughput and minimize wasteProduct Specification

| S/L | Source Feature/Finding | Customer Requirement |

| 01 | 1. Type of cutting: Top blade rotary, bottom blade fixed 2. weight of paper: 60-550gsm 3..reel diameter: Max 1800mm 4. Finished width: Max 1400mm 5. Finished sheet-Length: Min.450-Max.1650 mm 6. Num.of rolls cutting: 2 rolls 7. Cutting accuracy: ±0.3mm 8. Max.speed of cutting: 350cuts/min 9. Max.cutting speed: 300m/min 10.Delivery pile height: 1500mm 11. Requirement of the air pressure: 0.8MPa 12. Voltage: AC380V/220V, 50Hz 13. Main motor power: 11kW | Paper Cutting Machine (Roll to Sheet) Paper Width: 1100mm (Maximum) Sheet Stacker Required Automatic Loading System |

Advantage & Features

- High speed and accuracy: operates at 300 meters per minute, 300 cuts per minute, with a precision of ±0.5mm.

- Equipped with a PLC control system featuring automatic tension control, sheet counting, stacking, and mark insertion.

- The hydraulic unwinding unit allows for easy loading of paper jumbo rolls into the machine.

- The collection unit efficiently gathers the finished cut sheets onto a pallet.

- Includes a slitting unit capable of cutting the paper web into two sheets and trimming waste edges simultaneously.

- The machine automatically counts and inserts marking labels into stacks based on preset numbers via the touchscreen interface.

- The machine frame is made of 25mm thick steel, ensuring excellent stability during high-speed operation.

The FKT-SCS1400 automatic paper cutting machine is ideal for high-volume industrial use:

- Paper Mills: Converts jumbo rolls into finished, stacked, and counted sheets for bulk distribution.

- Printing Presses: Feeds digital and offset presses efficiently, removing sheet-preparation bottlenecks.

- Packaging Converters: Cuts materials from light liners to 550 GSM cardboard, perfect for FMCG and RMG packaging.

- Publishing & Education: Delivers high-speed, precise cutting for large-scale writing and printing paper production.

Specification

Paper Cutting Machine (Roll to Sheet)

This digital paper cutting machine converts jumbo paper rolls into perfectly cut, press-ready sheets with unmatched precision. Offering a strategic 60-550 GSM versatility, this is the ultimate paper cutting machine for high-volume paper mills, printers, and packaging converters looking to maximize throughput and minimize wasteProduct Specification

| S/L | Source Feature/Finding | Customer Requirement |

| 01 | 1. Type of cutting: Top blade rotary, bottom blade fixed 2. weight of paper: 60-550gsm 3..reel diameter: Max 1800mm 4. Finished width: Max 1400mm 5. Finished sheet-Length: Min.450-Max.1650 mm 6. Num.of rolls cutting: 2 rolls 7. Cutting accuracy: ±0.3mm 8. Max.speed of cutting: 350cuts/min 9. Max.cutting speed: 300m/min 10.Delivery pile height: 1500mm 11. Requirement of the air pressure: 0.8MPa 12. Voltage: AC380V/220V, 50Hz 13. Main motor power: 11kW | Paper Cutting Machine (Roll to Sheet) Paper Width: 1100mm (Maximum) Sheet Stacker Required Automatic Loading System |

Advantage & Features

Advantage & Features

- High speed and accuracy: operates at 300 meters per minute, 300 cuts per minute, with a precision of ±0.5mm.

- Equipped with a PLC control system featuring automatic tension control, sheet counting, stacking, and mark insertion.

- The hydraulic unwinding unit allows for easy loading of paper jumbo rolls into the machine.

- The collection unit efficiently gathers the finished cut sheets onto a pallet.

- Includes a slitting unit capable of cutting the paper web into two sheets and trimming waste edges simultaneously.

- The machine automatically counts and inserts marking labels into stacks based on preset numbers via the touchscreen interface.

- The machine frame is made of 25mm thick steel, ensuring excellent stability during high-speed operation.

Applications

The FKT-SCS1400 automatic paper cutting machine is ideal for high-volume industrial use:

- Paper Mills: Converts jumbo rolls into finished, stacked, and counted sheets for bulk distribution.

- Printing Presses: Feeds digital and offset presses efficiently, removing sheet-preparation bottlenecks.

- Packaging Converters: Cuts materials from light liners to 550 GSM cardboard, perfect for FMCG and RMG packaging.

- Publishing & Education: Delivers high-speed, precise cutting for large-scale writing and printing paper production.

Product Comparison

Product Comparison Table with Similar Products

| Specification | FKT-SCS1400 Paper Cutting Machine | GW-S140 | CHM-1400 | Vatan Makina FCT-1450 |

| Max Line Speed | 300 m/min | 300 m/min | 300 m/min | 300 m/min |

| Paper GSM Range | 60-550 GSM | (Not Listed) | 60-550 GSM | 40-500 GSM |

| Cutting Precision | ±0.3mm | ±0.3mm | ±0.5mm | ±0.25mm |

| Key Advantage | Widest Versatility & High-Precision Option | Siemens PLC | Matches GSM Range | Good Standard Precision |

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The FKT-SCS1400 Paper Cutting Machine (Roll to Sheet) comes with a service warranty that covers technical malfunctions and performance issues related to the machine’s core paper cutting and roll-to-sheet conversion functions. Certain components—such as blades, rollers, belts, and other consumable parts—are subject to natural wear and tear and are therefore not covered under this warranty. If any covered part experiences a malfunction within the warranty period, our trained technicians will provide the necessary repair or replacement service. However, customers will be responsible for purchasing any required spare parts. Please note that all shipping and transportation costs associated

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Product Warranty

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The FKT-SCS1400 Paper Cutting Machine (Roll to Sheet) comes with a service warranty that covers technical malfunctions and performance issues related to the machine’s core paper cutting and roll-to-sheet conversion functions. Certain components—such as blades, rollers, belts, and other consumable parts—are subject to natural wear and tear and are therefore not covered under this warranty. If any covered part experiences a malfunction within the warranty period, our trained technicians will provide the necessary repair or replacement service. However, customers will be responsible for purchasing any required spare parts. Please note that all shipping and transportation costs associated

Technical & After Sales Service

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Company Info

Prominent Tec Company Information

Address: House #9, Block #A, Road #1, Niketon, Dhaka-1212, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.

Q1. What is the difference between this automatic paper cutting machine and a guillotine cutter?

A1. A guillotine cuts stacks, while the FKT-SCS1400 converts jumbo rolls into sheets. It’s a continuous system, not batch-based.

Q2. How many operators are needed for this digital paper cutting machine?

A2. One trained operator can run it with hydraulic loading and automatic stacking.

Q3. Is this digital paper cutting machine suitable for heavy cardboard?

A3 Yes, it handles 60–550 GSM materials like cardboard, kraft, and coated paper.

Q4: Is local service and support available for this Paper Cutting Machine?

Yes, Prominent Tec in Bangladesh offers installation, training, service, and spare parts.