D-Tex Digital Label Printing Machine for High-Speed, Full-Color Labels

Unlock the future of apparel labeling with the d-Tex digital label printing system. Designed for the dynamic demands of Bangladesh’s garment industry, this advanced digital label printer machine offers unparalleled speed, precision, and flexibility for short-run production of high-quality fabric labels.

- Model name: PT

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months

- Packaging: Standard Export Wooden Case

Share:

Request a quote for

D-Tex Digital Label Printing Machine for High-Speed, Full-Color Labels

Unlock the future of apparel labeling with the d-Tex digital label printing system. Designed for the dynamic demands of Bangladesh’s garment industry, this advanced digital label printer machine offers unparalleled speed, precision, and flexibility for short-run production of high-quality fabric labels.

- Model name: PT

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months

- Packaging: Standard Export Wooden Case

Share:

Product Info

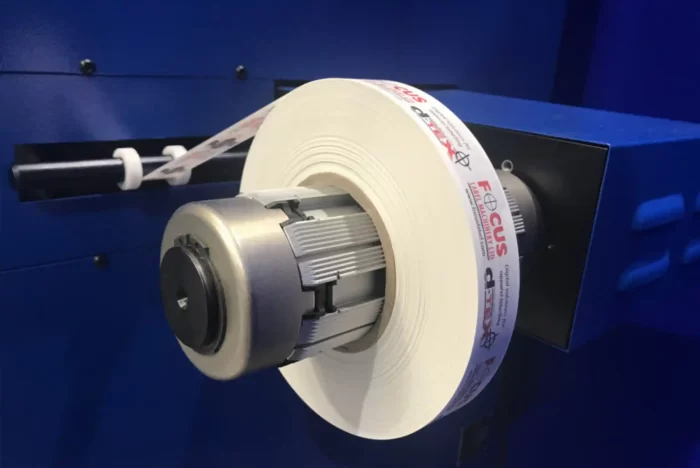

D-Tex Digital Label Printing

Experience rapid turnarounds, vibrant full-color printing, and significant cost savings with this cutting-edge printer for labels, ideal for variable data and intricate designs.Product Specification

| Feature | Specification |

| Product Name | d-Tex Digital Printing System |

| Manufacturer | Focus Label Machinery Ltd. |

| Country of Origin | United Kingdom |

| Printing Technology | High-Speed Inkjet |

| Color Configuration | 2-color (MK – Magenta/Key/Black) or Full-Color (CMYK – Cyan, Magenta, Yellow, Black) |

| Print Speed | 30-60 meters per minute (approx. 98-197 feet per minute) |

| Resolution | High-resolution capability for crisp graphics and fine text |

| Substrate Compatibility | Primarily garment and apparel labels (e.g., satin, polyester, nylon tapes, woven edge materials, narrow fabrics) |

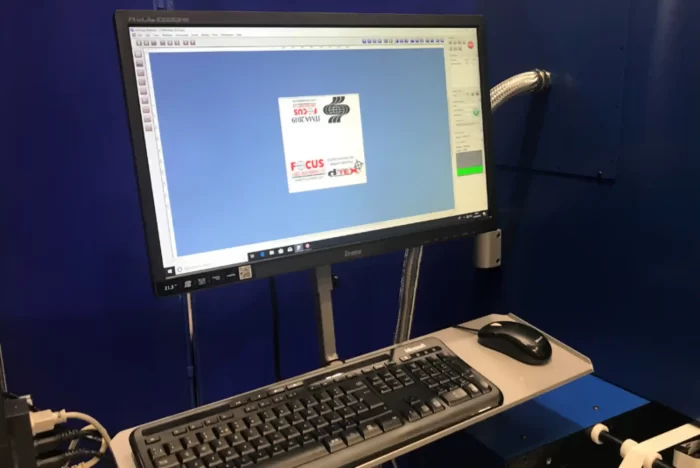

| Software Integration | High-end software for seamless variable data printing and graphic file management |

| Production Range | Optimal for short to medium runs, typically 10 to 100,000 labels |

| Energy Efficiency | Optimized for reduced power consumption during operation |

| Environmental Design | Engineered to minimize waste, water usage, and chemical discharge compared to conventional methods |

Advantage & Features

The d-Tex digital label printing system gives a strong competitive edge in Bangladesh’s fast-paced garment sector. More than just a printer, it’s a smart investment.

Accelerated Production & Turnaround:

Prints 30–60 meters/min with quick setup—no plates needed. Move from design to label in minutes and meet urgent demands.

Cost-Effectiveness for Short & Medium Runs:

No costly plates or screens—ideal for short runs. Reduces setup waste and material costs, maximizing ROI.

Unrivaled Print Quality & Detail:

High-resolution inkjet tech delivers vivid colors, sharp text, and precise designs—boosting brand image.

Supreme Design Flexibility & Variable Data Capability:

Easily prints unique serials, barcodes, QR codes, and messages—perfect for tracking, anti-counterfeiting, and customization.

Sustainable Manufacturing Practices:

Low waste, minimal water and chemical use—eco-friendly and meets global sustainability standards.

Enhanced Profitability & Market Responsiveness:

Fast job changeovers and on-demand printing reduce inventory and free up capacity—driving profits and quick trend adaptation.

Applications

The versatility and efficiency of the d-Tex digital label printing system make it an ideal solution for a broad spectrum of labeling requirements within Bangladesh’s vibrant manufacturing landscape, particularly in the textile sector.

- Garment & Apparel Labels: The core application, including high-quality care labels, prominent brand labels, precise size labels, detailed composition labels, and country-of-origin tags for all types of clothing – from high fashion to everyday wear. The ability to print variable data is crucial for garment serialization.

- Fashion Accessories Labels: Perfect for producing labels for scarves, hats, bags, footwear, belts, and other accessories where branding, material information, and care instructions are vital.

- Home Textile Labels: Suitable for durable labels on bedding, towels, curtains, upholstery, and carpets, ensuring information withstands regular use and washing.

- Sportswear & Activewear Labels: Creates robust, wash-fast labels that can endure the rigors of athletic performance and frequent washing, maintaining legibility and integrity.

- Children’s Clothing Labels: Ensures the production of soft, non-irritating, and legally compliant labels for children’s wear, adhering to strict safety standards.

- Promotional & Event Ribbons: Offers a cost-effective way to produce custom-branded ribbons, lanyards, and promotional tags for events, corporate gifts, and specialized product packaging.

- Industrial Narrow Fabric Printing: Extends beyond apparel to various industrial narrow fabrics that require durable, digitally printed identification or functional markings.

Specification

D-Tex Digital Label Printing

Experience rapid turnarounds, vibrant full-color printing, and significant cost savings with this cutting-edge printer for labels, ideal for variable data and intricate designs.Product Specification

| Feature | Specification |

| Product Name | d-Tex Digital Printing System |

| Manufacturer | Focus Label Machinery Ltd. |

| Country of Origin | United Kingdom |

| Printing Technology | High-Speed Inkjet |

| Color Configuration | 2-color (MK – Magenta/Key/Black) or Full-Color (CMYK – Cyan, Magenta, Yellow, Black) |

| Print Speed | 30-60 meters per minute (approx. 98-197 feet per minute) |

| Resolution | High-resolution capability for crisp graphics and fine text |

| Substrate Compatibility | Primarily garment and apparel labels (e.g., satin, polyester, nylon tapes, woven edge materials, narrow fabrics) |

| Software Integration | High-end software for seamless variable data printing and graphic file management |

| Production Range | Optimal for short to medium runs, typically 10 to 100,000 labels |

| Energy Efficiency | Optimized for reduced power consumption during operation |

| Environmental Design | Engineered to minimize waste, water usage, and chemical discharge compared to conventional methods |

Advantage & Features

Advantage & Features

The d-Tex digital label printing system gives a strong competitive edge in Bangladesh’s fast-paced garment sector. More than just a printer, it’s a smart investment.

Accelerated Production & Turnaround:

Prints 30–60 meters/min with quick setup—no plates needed. Move from design to label in minutes and meet urgent demands.

Cost-Effectiveness for Short & Medium Runs:

No costly plates or screens—ideal for short runs. Reduces setup waste and material costs, maximizing ROI.

Unrivaled Print Quality & Detail:

High-resolution inkjet tech delivers vivid colors, sharp text, and precise designs—boosting brand image.

Supreme Design Flexibility & Variable Data Capability:

Easily prints unique serials, barcodes, QR codes, and messages—perfect for tracking, anti-counterfeiting, and customization.

Sustainable Manufacturing Practices:

Low waste, minimal water and chemical use—eco-friendly and meets global sustainability standards.

Enhanced Profitability & Market Responsiveness:

Fast job changeovers and on-demand printing reduce inventory and free up capacity—driving profits and quick trend adaptation.

Applications

Applications

The versatility and efficiency of the d-Tex digital label printing system make it an ideal solution for a broad spectrum of labeling requirements within Bangladesh’s vibrant manufacturing landscape, particularly in the textile sector.

- Garment & Apparel Labels: The core application, including high-quality care labels, prominent brand labels, precise size labels, detailed composition labels, and country-of-origin tags for all types of clothing – from high fashion to everyday wear. The ability to print variable data is crucial for garment serialization.

- Fashion Accessories Labels: Perfect for producing labels for scarves, hats, bags, footwear, belts, and other accessories where branding, material information, and care instructions are vital.

- Home Textile Labels: Suitable for durable labels on bedding, towels, curtains, upholstery, and carpets, ensuring information withstands regular use and washing.

- Sportswear & Activewear Labels: Creates robust, wash-fast labels that can endure the rigors of athletic performance and frequent washing, maintaining legibility and integrity.

- Children’s Clothing Labels: Ensures the production of soft, non-irritating, and legally compliant labels for children’s wear, adhering to strict safety standards.

- Promotional & Event Ribbons: Offers a cost-effective way to produce custom-branded ribbons, lanyards, and promotional tags for events, corporate gifts, and specialized product packaging.

- Industrial Narrow Fabric Printing: Extends beyond apparel to various industrial narrow fabrics that require durable, digitally printed identification or functional markings.

Product Comparison

Product Comparison Table with Similar Products

| Feature | d-Tex Digital Label Printing (for Fabrics) | Traditional Flexographic Label Printing (for Fabrics) | Traditional Screen Printing (for Fabrics) |

| Technology Type | Inkjet, Digital Direct-to-Fabric | Rotary Plate-based, Analog | Mesh Screen-based, Analog |

| Primary Use Case | Short to medium runs, variable data, high-quality, quick turnaround | Long runs, static designs, large volume, established brand labels | Medium runs, bold colors, specific tactile effects, heat transfers |

| Setup Time | Minutes (digital file upload & machine calibration) | Hours (plate making, ink mixing, press registration) | Hours (screen preparation, emulsion, drying, registration) |

| Plates/Screens Needed | None (Direct digital transfer) | Yes (costly, unique plates per color/design, long lead time for changes) | Yes (screens per color/design, manual preparation, easily damaged) |

| Cost for Short Runs | Very Cost-Effective (zero plate costs, minimal waste, rapid changeovers) | High (due to significant fixed setup costs of plates) | High (due to screen preparation time & costs) |

| Design Flexibility | Excellent (unlimited colors, intricate details, seamless variable data) | Moderate (changes require new plates, design static once plates made) | Limited (difficult for gradients, complex multi-color, no variable data) |

| Color Capability | 2-color (MK) or Full-Color (CMYK) for photorealistic prints | Spot colors, Full-Color possible but requires more plates/complexity | Spot colors, vibrant but limited by screen count |

| Resolution/Detail | High-definition, sharp edges, fine text, smooth gradients | Good, but resolution dependent on plate quality and press capabilities | Good for solids, but finer details and gradients can be challenging |

| Minimum Order Qty. | Very Low (e.g., 10 labels, ideal for prototyping or small collections) | Higher (to amortize setup costs effectively) | Higher (to justify screen setup costs) |

| Waste Generation | Minimal (less material wasted during setup, precise ink usage) | Significant (wasteful during setup, color matching, and registration) | Moderate (ink waste, cleaning solvents, damaged screens) |

| Environmental Impact | Lower (reduced water, chemicals, no plate disposal, less energy) | Higher (chemical usage for plate processing, water, plate disposal) | Higher (chemical usage for screen reclamation, water, ink waste) |

| Market Adoption in Bangladesh | Rapidly growing due to export demands for speed, customization, and sustainability in RMG sector. | Established, widely used for bulk orders, but increasingly challenged by digital’s agility. | Common for simpler labels and heat transfers, but less adaptable for modern needs. |

| Hidden Costs/Benefits | Reduced inventory, quicker response to trends, premium pricing for custom orders, lower obsolescence. | Large inventory needed, less responsive to market shifts, potential for outdated stock. | Can offer unique tactile feel, but less efficient for diverse orders. |

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The D-Tex Digital Label Printing comes with a service warranty that covers core system functions, including electronics, control panels, and mechanical drive components. Some items—like printheads, ink filters, capping stations, wiper blades, and other consumables—naturally wear out over time and are considered consumables, so they aren’t covered under the warranty. If any covered part stops working during the warranty period, our technicians will handle the repair or replacement, but customers will need to purchase any necessary spare parts. Please note that customers are responsible for all shipping costs when sending or receiving parts or equipment.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Product Warranty

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The D-Tex Digital Label Printing comes with a service warranty that covers core system functions, including electronics, control panels, and mechanical drive components. Some items—like printheads, ink filters, capping stations, wiper blades, and other consumables—naturally wear out over time and are considered consumables, so they aren’t covered under the warranty. If any covered part stops working during the warranty period, our technicians will handle the repair or replacement, but customers will need to purchase any necessary spare parts. Please note that customers are responsible for all shipping costs when sending or receiving parts or equipment.

Technical & After Sales Service

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Company Info

Prominent Tec Company Information

Address: House #9, Block #A, Road #1, Niketon, Dhaka-1212, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.

Q1: What types of fabric materials can the d-Tex digital label printer handle?

A1: It prints on narrow fabrics like satin, polyester, nylon tapes, and some woven-edge materials used for garment labels.

Q2: How does the d-Tex digital label printing system benefit short-run label production?

A2: It eliminates costly plates and reduces setup time and waste, making small batch and custom orders more profitable.

Q3: Can this digital label printer machine produce full-color labels?

A3: Yes, it supports full-color (CMYK) printing for vibrant, complex graphics, with a 2-color (MK) option for simpler designs.

Q4: Is the ink used by the d-Tex system durable and wash-resistant for garment labels?

A4: Yes, it uses textile inks with excellent wash fastness, ensuring long-lasting, legible labels.

Q5: What is the typical ROI for investing in a d-Tex digital label printer in Bangladesh?

A5: ROI is high due to lower costs, fast turnaround, and the ability to handle custom, value-added orders efficiently.

Q6: Does Focus Label Machinery provide support or training for the d-Tex system?

A6: Yes, Focus offers installation, training, and technical support—buyers in Bangladesh should contact them directly for local options.