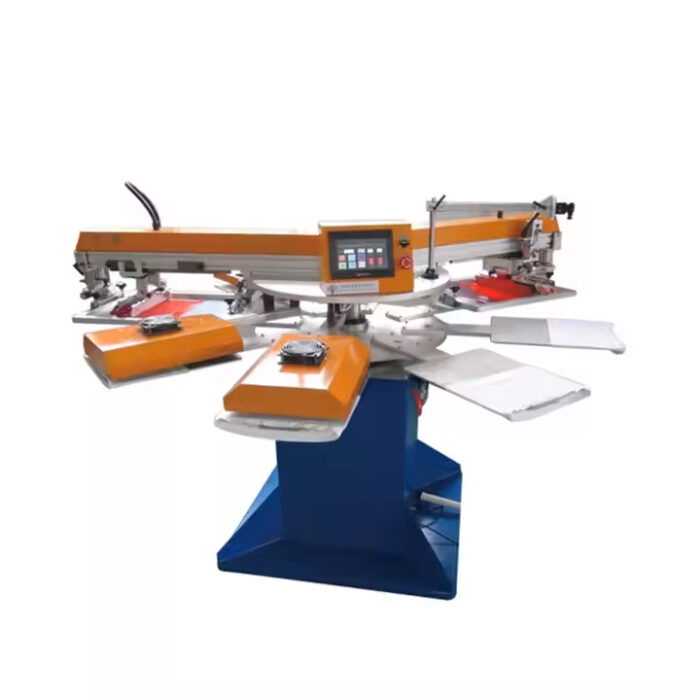

Round Shape Automatic Screen Printing Machine for T-Shirts & Fabrics

In Bangladesh’s rapidly expanding manufacturing landscape, the demand for efficient and high-quality printing solutions is paramount. The PT-A2 round shape color automatic screen printing machine emerges as a powerful answer, offering a blend of speed, precision, and versatility that can significantly boost productivity and product quality.

- Model name: PT-A2

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months.

- Packaging: Standard Export Wooden Case

Share:

Request a quote for

Round Shape Automatic Screen Printing Machine for T-Shirts & Fabrics

In Bangladesh’s rapidly expanding manufacturing landscape, the demand for efficient and high-quality printing solutions is paramount. The PT-A2 round shape color automatic screen printing machine emerges as a powerful answer, offering a blend of speed, precision, and versatility that can significantly boost productivity and product quality.

- Model name: PT-A2

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months.

- Packaging: Standard Export Wooden Case

Share:

Product Info

Round Shape Automatic Screen Printing Machine

For businesses specializing in textiles, labels, and various other industrial applications, this machine is available at a low price point for its capabilities. This cutting-edge automatic silk screen printing machine, featuring advanced technology, is designed to streamline operations, reduce labor costs, and deliver consistent results, making it an invaluable asset for forward-thinking enterprises.Product Specification

| Model | Single color | Double color |

| Printing station | 6pcs | 8pcs |

| Printing area | 100*150mm | 300*300mm |

| Table size | 120*220mm | 320*400mm |

| Drying oven | 2pcs | 3pcs |

| Machine diameter | 2000mm | 2000mm |

| Printing speed | 500-1000pcs/hour | 500-1000pcs/hour |

| Drying oven power | 3*200w/unit | 3kw/set |

| Cooling fan | 1set | 1set |

| Voltage | 220v,50Hz | 380v,50HZ |

| Max power | 1500W | 10KW |

Advantage & Features

- The machine offers three operating modes—manual, single-cycle, and fully automatic—so you can choose the operation mode that fits your workflow best. A popular configuration is the 2 colors 8 stations model, but other setups are available.

- The worktable, or printing table, is made from aluminum alloy, which keeps it lightweight but still strong and sturdy.

- You can adjust each printing arm individually to suit different printing needs.

- The machine uses both electricity and air pressure to control the squeegee, ink flow, and printing pressure—all of which you can fine-tune as needed.

- It supports repeat printing with a preset counter (from 1 to 9 times), making it easy to handle repetitive tasks.

- A dependable PLC control system keeps everything running smoothly.

- It comes with a near-infrared drying lamp that includes a flash function. You can set the drying time and even extend it if needed.

- The touchscreen interface is easy to use and supports both English and Chinese.

- You can adjust the angle and height of the squeegee blade to make sure the printing pressure stays consistent across the surface.

- The user interface is clear, simple, and intuitive—thanks to the smart plc system that makes operation hassle-free.

Applications

- Textile and Garment Printing: This is a primary application. The machine excels at printing on T-shirts, hoodies, sportswear, and various cut-piece garments. Its rotary silk screen printing machine design is highly efficient for high-volume textile production.

- Label Printing: Ideal for printing intricate designs on garment labels, woven labels, and heat transfer labels that may use a special adhesive backing, ensuring high precision and vibrant colors.

- Fabric Printing: Suitable for printing patterns and designs on different types of fabrics, including cotton, polyester, and blends. For optimal results, screen preparation using a stretching machine is recommended.

- Non-Woven Bag Printing: Efficiently prints logos and designs on reusable non-woven shopping bags, a growing market segment.

- Specialty Material Printing: The machine’s versatility extends to printing on flat or cylindrical items, including materials like ceramic and glass, expanding a business’s service offerings.

- Promotional Products: Can be used to print on various flat promotional items.

Specification

Round Shape Automatic Screen Printing Machine

For businesses specializing in textiles, labels, and various other industrial applications, this machine is available at a low price point for its capabilities. This cutting-edge automatic silk screen printing machine, featuring advanced technology, is designed to streamline operations, reduce labor costs, and deliver consistent results, making it an invaluable asset for forward-thinking enterprises.Product Specification

| Model | Single color | Double color |

| Printing station | 6pcs | 8pcs |

| Printing area | 100*150mm | 300*300mm |

| Table size | 120*220mm | 320*400mm |

| Drying oven | 2pcs | 3pcs |

| Machine diameter | 2000mm | 2000mm |

| Printing speed | 500-1000pcs/hour | 500-1000pcs/hour |

| Drying oven power | 3*200w/unit | 3kw/set |

| Cooling fan | 1set | 1set |

| Voltage | 220v,50Hz | 380v,50HZ |

| Max power | 1500W | 10KW |

Advantage & Features

Advantage & Features

- The machine offers three operating modes—manual, single-cycle, and fully automatic—so you can choose the operation mode that fits your workflow best. A popular configuration is the 2 colors 8 stations model, but other setups are available.

- The worktable, or printing table, is made from aluminum alloy, which keeps it lightweight but still strong and sturdy.

- You can adjust each printing arm individually to suit different printing needs.

- The machine uses both electricity and air pressure to control the squeegee, ink flow, and printing pressure—all of which you can fine-tune as needed.

- It supports repeat printing with a preset counter (from 1 to 9 times), making it easy to handle repetitive tasks.

- A dependable PLC control system keeps everything running smoothly.

- It comes with a near-infrared drying lamp that includes a flash function. You can set the drying time and even extend it if needed.

- The touchscreen interface is easy to use and supports both English and Chinese.

- You can adjust the angle and height of the squeegee blade to make sure the printing pressure stays consistent across the surface.

- The user interface is clear, simple, and intuitive—thanks to the smart plc system that makes operation hassle-free.

Applications

Applications

- Textile and Garment Printing: This is a primary application. The machine excels at printing on T-shirts, hoodies, sportswear, and various cut-piece garments. Its rotary silk screen printing machine design is highly efficient for high-volume textile production.

- Label Printing: Ideal for printing intricate designs on garment labels, woven labels, and heat transfer labels that may use a special adhesive backing, ensuring high precision and vibrant colors.

- Fabric Printing: Suitable for printing patterns and designs on different types of fabrics, including cotton, polyester, and blends. For optimal results, screen preparation using a stretching machine is recommended.

- Non-Woven Bag Printing: Efficiently prints logos and designs on reusable non-woven shopping bags, a growing market segment.

- Specialty Material Printing: The machine’s versatility extends to printing on flat or cylindrical items, including materials like ceramic and glass, expanding a business’s service offerings.

- Promotional Products: Can be used to print on various flat promotional items.

Product Comparison

Product Comparison Table

| Feature | PT-A2 (Round) | PT-A2 (Round) | Anatol Volt (Rotary) | ROQprint ECO (Rotary) | M&R Sportsman® EX (Rotary) | Systematic Automation (Cylindrical/Rotary) |

| Max Colors | 1 | 2 | 4-18 (up to 20 stations) | 8-18 (up to 20 pallets) | 6-12 | 1-6 |

| Max Stations/Pallets | 6 | 8 | 6-20 | 10-20 | 6-12 | Varies by model |

| Max Print Area | 100x150mm | 300x300mm | 15″x16″ to 20″x28″ | 480x630mm to 700x1000mm | 16″x18″ to 20″x28″ | Varies, e.g., small format |

| Printing Speed | 500-1000 Pcs/h | 500-1000 Pcs/h | Up to 900 Pcs/h (ROQ E) | Up to 1300 Pcs/h | Not specified directly, “higher speeds” | Up to 4300 parts/hour (Vinci) |

| Voltage | 220V 50Hz | 380VA 50Hz | 1/3 ph 208/230V, 50/60Hz | 230V+N, 2x230V, 3x230V, 3x400V+N | 208/230V, 380/415V, 50/60Hz | Varies |

| Max Power | 1.5KW | 10KW | 11A-38A (3ph) | 5.5-6 kVA (ROQ E) | 3.3-6 kW | Varies |

| Key Drive System | Mechanical | Mechanical | Electric | Electric/AC Servo Motor | Electric/Servo-Driven | Varies, e.g., Servo-driven |

| Air Compressor Req. | Yes (Pneumatic squeegee clamping) | Yes (Pneumatic squeegee clamping) | No (All-electric Volt) | No (ROQ E built-in) | Yes (Pneumatic squeegee/floodbar locks) | Varies |

Warranty and Technical Support

Warranty Period: 12 Months.

Warranty Terms: The Round Shape Automatic Screen Printing Machine is backed by service warranty that includes coverage for its key electrical parts, pneumatic system, and integrated control modules. As with other models, consumable items such as heating elements, rubber seals, and pressure rings are excluded from warranty coverage due to their natural wear during regular production cycles. In case of failure in any of the covered components, our technical support team will offer repair or replacement services; however, customers are required to purchase any necessary spare parts separately. All transportation expenses for both inbound and outbound shipments must be borne by the customer.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Product Warranty

Warranty and Technical Support

Warranty Period: 12 Months.

Warranty Terms: The Round Shape Automatic Screen Printing Machine is backed by service warranty that includes coverage for its key electrical parts, pneumatic system, and integrated control modules. As with other models, consumable items such as heating elements, rubber seals, and pressure rings are excluded from warranty coverage due to their natural wear during regular production cycles. In case of failure in any of the covered components, our technical support team will offer repair or replacement services; however, customers are required to purchase any necessary spare parts separately. All transportation expenses for both inbound and outbound shipments must be borne by the customer.

Technical & After Sales Service

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Company Info

Company Information

Address: House #9, Block #A, Road #1, Niketon, Dhaka-1212, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries.

With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.

Q1: What is a silk screen printing machine?

A machine that transfers ink through a mesh stencil onto fabric or other materials—modern versions are fast and automated.

Q2: How does the PT-A2 work?

It rotates garments through multiple print stations for automatic inking, curing, and high-speed production.

Q3: What are its advantages over manual printing?

It offers faster output, better consistency, lower labor costs, and higher print accuracy for bulk jobs.

Q4: What can it print on?

T-shirts, garments, fabric cut-pieces, woven labels, non-woven bags, and even some rigid materials like glass and ceramic—perfect for diverse industries.

Q5: How fast is it?

It prints up to 1200 pieces per hour, making it ideal for large-scale T-shirt production.

Q6: Is it easy to operate?

Yes, it has a user-friendly touchscreen and PLC system that simplifies the entire process.

Q7: Does it include drying?

Yes, built-in infrared flash dryers cure the ink instantly at each station.

Q8: How precise is it for multi-color prints?

It ensures ±0.03mm accuracy using servo indexing for perfect color alignment.

Q9: Why should I buy it for my business in Bangladesh?

It offers the best price for its level of performance, boosts efficiency, reduces labor, and meets the growing demand for quality garment printing.