High-Speed Oval Automatic Screen Printing Machine for Bulk Textile Printing

The Oval Automatic Screen Printing Machine delivers high-efficiency performance for textile and garment printing, making it ideal for businesses aiming to scale production without compromising print quality. This is a key brand advantage for any growing apparel business.

- Model name: PT-J6

- Payment Method: L/C at sight or T/T in advance

- Min. Order: 01

- Warranty: 12 Months.

- Packaging: Standard Export Wooden Case

Share:

Request a quote for

High-Speed Oval Automatic Screen Printing Machine for Bulk Textile Printing

The Oval Automatic Screen Printing Machine delivers high-efficiency performance for textile and garment printing, making it ideal for businesses aiming to scale production without compromising print quality. This is a key brand advantage for any growing apparel business.

- Model name: PT-J6

- Payment Method: L/C at sight or T/T in advance

- Min. Order: 01

- Warranty: 12 Months.

- Packaging: Standard Export Wooden Case

Share:

Product Info

Oval Automatic Screen Printing Machine for Garments and Textile Printing

The Oval Automatic Screen Printing Machine delivers high-efficiency performance for textile and garment printing, making it ideal for businesses aiming to scale production without compromising print quality. This is a key brand advantage for any growing apparel business. Engineered for precision and durability, this machine integrates user-friendly controls, fast setup, and consistent output—features that streamline operations and boost productivity.Oval Automatic Screen Printing Machine Specification

| (standard version) | |||||||||||||||

| Model | unit | 2S | 4S | 6S | 8S | 10S | 12S | 14S | 16S | 18S | 20S | 22S | 24S | 26S | 28S |

| Plate Quantities | (piece) | 10 | 16 | 22 | 28 | 34 | 40 | 46 | 52 | 58 | 64 | 70 | 76 | 82 | 88 |

| Printing Number | (color) | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

| Printing Size | (cm) | 63*86.5(The printing area:60*70) | |||||||||||||

| Max Frame | (cm) | External dimension: width 72* length 102 | |||||||||||||

| Min Frame | (cm) | Outside dimension: width 52* length 50 | |||||||||||||

| Machine length | (cm) | 712 | 935 | 1158 | 1381 | 1604 | 1827 | 2050 | 2273 | 2496 | 2719 | 2942 | 3165 | 3388 | |

| Machine width | (cm) | 330(Do not add flash drying) | |||||||||||||

| Machine Height | (cm) | 156 | |||||||||||||

| Maximum component size | (cm) | 271*150*156 | |||||||||||||

| Maximum component weight | (kg) | 420 | |||||||||||||

| Machine weight | (kg) | 1828 | 2583 | 3338 | 4093 | 4848 | 5603 | 6358 | 7113 | 7868 | 8623 | 9378 | 10133 | 10888 | |

| Air consumption | (m3/minute) | 0.05 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.55 | 0.6 | 0.65 | 0.7 |

| Air pressure Specification | 0.6Mpa/0.8Mpa(It must be dried and filtered) | ||||||||||||||

| Print Head Driver | (W) | Single head servo motor 400W | |||||||||||||

| Total power Consumption | (KW/hour) | 2.7 | 3.5 | 4.3 | 5.2 | 5.9 | 6.7 | 7.5 | 8.5 | 9.8 | 10.6 | 11.4 | 12.2 | 13 | 13.8 |

| Power supply parameters | Three phase 380V/50HZ | ||||||||||||||

| Production capacity | (pieces/hour) | 700-800 | |||||||||||||

| Optional scraper size | (cm) | 60,55,50,45,40,35,30,25,20(45 for standard) | |||||||||||||

| Optional ink return knife size | (cm) | 61,56,51,46,41,36,31,26,21(46 for standard) | |||||||||||||

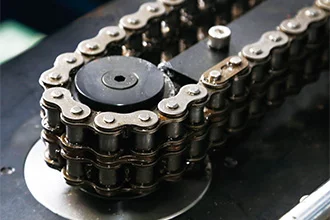

| No chain drive, setting accuracy ±0.02mm | |||||||||||||||

Advantage & Features

- Independent Multi-Function Heads: Each print head of Oval Automatic Screen Printing Machine operates independently, allowing for complex jobs that might otherwise require double procedures. They are equipped with an internally lubricated copper ring connecting rod for smooth performance.

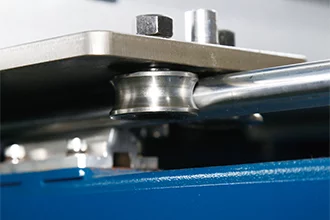

- Low-Noise T-Track Guide Rail: The T-shaped guide rail, powered by a precision servo drive, ensures quiet and smooth operation.

- Integrated Air Storage: Each print head of Oval Automatic Screen Printing Machine includes a dedicated air storage tank for consistent pneumatic performance.

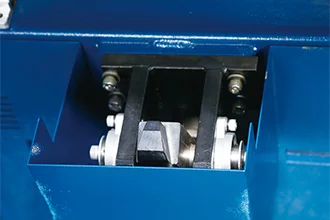

- Quick-Release Squeegee & Screen System: Pneumatic clamping allows for fast and stable clamping of the squeegee and locking for replacement. The ink-return blade works more efficiently, making the entire process incredibly time-saving. This system also simplifies version adjustment, allowing for precise setup of each new screen version.

- Enhanced Safety Lock: A built-in safety mechanism on each print head prevents unintentional movement, making operation safer and easier.

- Overall Steel Frame Structure: The machine is constructed with an overall steel frame structure that is full of materials, making it exceptionally durable and strong. This enhances stability and provides significant load-bearing capacity.

- Fast Plate Swapping: You can easily switch between ready-made garments and cut pieces with a one-touch board return system. The system is designed to realize quick plate change; the automatic leveling and seamless process of changing the board takes just seconds—no need to pause production.

- Ergonomic Platform Design: The platform is robust enough to support a person standing on it, highlighting its structural integrity.

- Honeycomb Plate Advantage: This feature enhances the structure of the full automatic screen printing machine. Its light weight design, paired with an upgraded new trolley system, reduces machine load. As a result, the plate runs faster, which increases speed, enhances stability, and boosts production output by up to 20%. It also allows for fast heating and fast cooling.

- Energy-Efficient S-Shaped Tube: The optimized tubing design cuts energy consumption by 40%, which can nearly save half of the power costs associated with drying.

Applications

- T-Shirt & Casual Wear Printing: Oval Automatic Screen Printing Machine is ideal for mass production of branded and custom t-shirts, polo shirts, hoodies, and sweatshirts. Ensures consistent quality across bulk orders, making it suitable for fashion labels, promotional merchandise, and export garments.

- Sportswear & Activewear Printing: Handles high-stretch fabrics like polyester and spandex blends used in jerseys, leggings, and gym wear. Supports plastisol and water-based inks for vibrant, durable, and flexible prints.

- Uniform & Workwear Printing: Perfect for bulk printing of uniforms for schools, offices, factories, and security services. Delivers sharp logos, badges, and text, maintaining brand identity at scale.

- Home Textile Printing: Suitable for printing on bedsheets, pillow covers, curtains, and cushion covers. Large platen options make it adaptable for oversized textile prints.

- Cut-Piece & Ready-Made Garments: Flexible board system allows switching between cut pieces and finished garments quickly. Saves production time, especially for factories working with both fabric panels and assembled clothing.

- Fashion & High-End Apparel: Oval Automatic Screen Printing Machine enables complex multicolor and special-effect printing (metallic, puff, discharge, glow-in-the-dark). Appeals to premium fashion brands looking for precision and creativity in bulk runs.

Specification

Oval Automatic Screen Printing Machine for Garments and Textile Printing

The Oval Automatic Screen Printing Machine delivers high-efficiency performance for textile and garment printing, making it ideal for businesses aiming to scale production without compromising print quality. This is a key brand advantage for any growing apparel business. Engineered for precision and durability, this machine integrates user-friendly controls, fast setup, and consistent output—features that streamline operations and boost productivity.Oval Automatic Screen Printing Machine Specification

| (standard version) | |||||||||||||||

| Model | unit | 2S | 4S | 6S | 8S | 10S | 12S | 14S | 16S | 18S | 20S | 22S | 24S | 26S | 28S |

| Plate Quantities | (piece) | 10 | 16 | 22 | 28 | 34 | 40 | 46 | 52 | 58 | 64 | 70 | 76 | 82 | 88 |

| Printing Number | (color) | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

| Printing Size | (cm) | 63*86.5(The printing area:60*70) | |||||||||||||

| Max Frame | (cm) | External dimension: width 72* length 102 | |||||||||||||

| Min Frame | (cm) | Outside dimension: width 52* length 50 | |||||||||||||

| Machine length | (cm) | 712 | 935 | 1158 | 1381 | 1604 | 1827 | 2050 | 2273 | 2496 | 2719 | 2942 | 3165 | 3388 | |

| Machine width | (cm) | 330(Do not add flash drying) | |||||||||||||

| Machine Height | (cm) | 156 | |||||||||||||

| Maximum component size | (cm) | 271*150*156 | |||||||||||||

| Maximum component weight | (kg) | 420 | |||||||||||||

| Machine weight | (kg) | 1828 | 2583 | 3338 | 4093 | 4848 | 5603 | 6358 | 7113 | 7868 | 8623 | 9378 | 10133 | 10888 | |

| Air consumption | (m3/minute) | 0.05 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.55 | 0.6 | 0.65 | 0.7 |

| Air pressure Specification | 0.6Mpa/0.8Mpa(It must be dried and filtered) | ||||||||||||||

| Print Head Driver | (W) | Single head servo motor 400W | |||||||||||||

| Total power Consumption | (KW/hour) | 2.7 | 3.5 | 4.3 | 5.2 | 5.9 | 6.7 | 7.5 | 8.5 | 9.8 | 10.6 | 11.4 | 12.2 | 13 | 13.8 |

| Power supply parameters | Three phase 380V/50HZ | ||||||||||||||

| Production capacity | (pieces/hour) | 700-800 | |||||||||||||

| Optional scraper size | (cm) | 60,55,50,45,40,35,30,25,20(45 for standard) | |||||||||||||

| Optional ink return knife size | (cm) | 61,56,51,46,41,36,31,26,21(46 for standard) | |||||||||||||

| No chain drive, setting accuracy ±0.02mm | |||||||||||||||

Advantage & Features

Advantage & Features

- Independent Multi-Function Heads: Each print head of Oval Automatic Screen Printing Machine operates independently, allowing for complex jobs that might otherwise require double procedures. They are equipped with an internally lubricated copper ring connecting rod for smooth performance.

- Low-Noise T-Track Guide Rail: The T-shaped guide rail, powered by a precision servo drive, ensures quiet and smooth operation.

- Integrated Air Storage: Each print head of Oval Automatic Screen Printing Machine includes a dedicated air storage tank for consistent pneumatic performance.

- Quick-Release Squeegee & Screen System: Pneumatic clamping allows for fast and stable clamping of the squeegee and locking for replacement. The ink-return blade works more efficiently, making the entire process incredibly time-saving. This system also simplifies version adjustment, allowing for precise setup of each new screen version.

- Enhanced Safety Lock: A built-in safety mechanism on each print head prevents unintentional movement, making operation safer and easier.

- Overall Steel Frame Structure: The machine is constructed with an overall steel frame structure that is full of materials, making it exceptionally durable and strong. This enhances stability and provides significant load-bearing capacity.

- Fast Plate Swapping: You can easily switch between ready-made garments and cut pieces with a one-touch board return system. The system is designed to realize quick plate change; the automatic leveling and seamless process of changing the board takes just seconds—no need to pause production.

- Ergonomic Platform Design: The platform is robust enough to support a person standing on it, highlighting its structural integrity.

- Honeycomb Plate Advantage: This feature enhances the structure of the full automatic screen printing machine. Its light weight design, paired with an upgraded new trolley system, reduces machine load. As a result, the plate runs faster, which increases speed, enhances stability, and boosts production output by up to 20%. It also allows for fast heating and fast cooling.

- Energy-Efficient S-Shaped Tube: The optimized tubing design cuts energy consumption by 40%, which can nearly save half of the power costs associated with drying.

Applications

Applications

- T-Shirt & Casual Wear Printing: Oval Automatic Screen Printing Machine is ideal for mass production of branded and custom t-shirts, polo shirts, hoodies, and sweatshirts. Ensures consistent quality across bulk orders, making it suitable for fashion labels, promotional merchandise, and export garments.

- Sportswear & Activewear Printing: Handles high-stretch fabrics like polyester and spandex blends used in jerseys, leggings, and gym wear. Supports plastisol and water-based inks for vibrant, durable, and flexible prints.

- Uniform & Workwear Printing: Perfect for bulk printing of uniforms for schools, offices, factories, and security services. Delivers sharp logos, badges, and text, maintaining brand identity at scale.

- Home Textile Printing: Suitable for printing on bedsheets, pillow covers, curtains, and cushion covers. Large platen options make it adaptable for oversized textile prints.

- Cut-Piece & Ready-Made Garments: Flexible board system allows switching between cut pieces and finished garments quickly. Saves production time, especially for factories working with both fabric panels and assembled clothing.

- Fashion & High-End Apparel: Oval Automatic Screen Printing Machine enables complex multicolor and special-effect printing (metallic, puff, discharge, glow-in-the-dark). Appeals to premium fashion brands looking for precision and creativity in bulk runs.

Product Comparison

Product Comparison Table

| Feature | PT-A1 Oval Automatic Screen Printing Machine | TYSL Oval Screen Printer | ROQprint Oval Evolution |

| Drive System | Full Servo Motor | Servo Motor | Servo Motor |

| Registration Acc. | $\pm$0.05mm | $\pm$0.05mm (approx.) | $\pm$0.025mm |

| Platen Material | Honeycomb Aluminum | Aluminum | Aluminum |

| Max. Print Area | Up to 800x1100mm | Up to 700x1000mm | Up to 1000x1400mm |

| Control System | Multi-Function Touch Screen | Advanced Touchscreen | Advanced PLC & Touchscreen |

| Quick Change System | Pneumatic Clamping & Quick Plate Change | Yes | Yes |

| Target Market | Cost-effective performance, automation focus | Reliability, robust build | High-end, ultimate precision, speed |

Warranty and Technical Support

Warranty Period: 12 Months.

Warranty Terms: The Oval Automatic Screen Printing Machine is backed by a service warranty that covers its essential electrical components, pneumatic system, and central control units. Due to regular usage, parts such as honeycomb pallets, rubber pads, and squeegee blades are classified as consumables and are not included under the warranty coverage. If any other covered component fails within the warranty period, our technicians will provide repair or replacement services; however, customers are required to purchase all necessary spare parts separately. Basic components like switches, wiring, or adjustment knobs qualify for a one-time replacement during the warranty term. All costs related to inbound and outbound shipping are the responsibility of the customers.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Product Warranty

Warranty and Technical Support

Warranty Period: 12 Months.

Warranty Terms: The Oval Automatic Screen Printing Machine is backed by a service warranty that covers its essential electrical components, pneumatic system, and central control units. Due to regular usage, parts such as honeycomb pallets, rubber pads, and squeegee blades are classified as consumables and are not included under the warranty coverage. If any other covered component fails within the warranty period, our technicians will provide repair or replacement services; however, customers are required to purchase all necessary spare parts separately. Basic components like switches, wiring, or adjustment knobs qualify for a one-time replacement during the warranty term. All costs related to inbound and outbound shipping are the responsibility of the customers.

Technical & After Sales Service

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Company Info

Company Information

Address: House #9, Block #A, Road #1, Niketon, Dhaka-1212, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries.

With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.

Q1: What’s the best machine for high-volume t-shirt printing?

The Oval Automatic Screen Printing Machine is a top pick—it’s fast, precise, and perfect for large orders.

Q2: Can the PT-A1 Oval Automatic Screen Printing Machine print on both ready-made clothes and cut pieces?

Yes, it works great for both finished garments and fabric pieces.

Q3: What types of ink work with the PT-A1 Oval Automatic Screen Printing Machine?

It handles plastisol, water-based, discharge, and special-effect inks easily.

Q4: Does the PT-A1 Oval Automatic Screen Printing Machine help save electricity?

Yes, it’s designed to use less power while keeping performance high.