Automatic Emulsion Coating Machine for Screen Printing

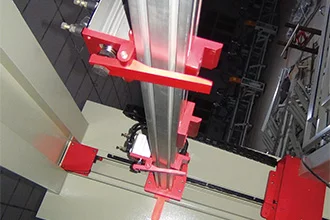

The PT-F High Quality Automatic Screen Emulsion Machine is a high-precision auto coater designed to apply emulsion on screen printing frames with maximum efficiency. This advanced Automatic Emulsion Coating Machine and its technology significantly enhance the quality and uniformity of emulsion layers, a step whose importance cannot be overstated for achieving sharp, detailed prints.

- Model name: PT-F

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months.

- Packaging: Standard Export Wooden Case

Share:

Request a quote for

Automatic Emulsion Coating Machine for Screen Printing

The PT-F High Quality Automatic Screen Emulsion Machine is a high-precision auto coater designed to apply emulsion on screen printing frames with maximum efficiency. This advanced Automatic Emulsion Coating Machine and its technology significantly enhance the quality and uniformity of emulsion layers, a step whose importance cannot be overstated for achieving sharp, detailed prints.

- Model name: PT-F

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months.

- Packaging: Standard Export Wooden Case

Share:

Product Info

Industrial Automatic Emulsion Coating Machine for Screen Printing

The PT-F Automatic Emulsion Coating Machine is ideal for screen printing and textile printing businesses in Bangladesh. It’s perfect for those upgrading from manual coating. The machine delivers full automation, saving labor and ensuring consistent results. It’s a smart investment for any modern textile or graphic printing operation.Product Specification

| Model | PT-G01 | PT-G02 |

| Max frame(Out) | 1000*1100mm | 1600*2400mm |

| Min frame(Out) | 600*600mm | 800*800mm |

| Coating speed | 50~150mm/sec | |

| Frame fixed way | Vacuum fixed clamp | |

| Air pressure | 6kg/c㎡ | |

| Weight | 550kg | 950kg |

| Power | 220V*1ph*450w | 220v*1ph*600w |

| Machine size(W X D X H) | 1920*580*1900mm | 2250*980*3300mm |

Advantage & Features

- Automatic Emulsion Coating Machine is equipped with a high-quality imported motor for smooth, vibration-free operation, ensuring a stable and even coating thickness.

- The PLC system allows you to choose single or double-sided coating, either manually or automatically, with real-time adjustments to the applicator speed.

- The robust structure, built from durable stainless steel, provides longevity and features built-in protection systems for safe operation.

- A special pressure system ensures even delicate materials receive a precise coating with the desired thickness.

- The screen holder can be adjusted up or down, making the loading and coating of screens of various sizes simple and efficient.

Applications

- Textile and Garment Printing: A key part of Bangladesh’s economy, screen printing is essential for t-shirts, fabrics, and ready-made garments. The PT-F Automatic Emulsion Coating Machine ensures precise coating for detailed designs before the screen goes to the printing press.

- Home Textile Industry: For products like bedsheets, curtains, and upholstery, the PT-F Automatic Emulsion Coating Machine helps prepare screens that deliver vibrant, long-lasting prints.

- Promotional and Custom Apparel: With growing demand for custom t-shirts and branded items, the PT-F Automatic Emulsion Coating Machine enables fast and reliable screen prep for quick delivery.

- Industrial and Graphic Screen Printing: The PT-F Automatic Emulsion Coating Machine also supports printing on signage, ceramics, plastics, and electronics—offering the precision and consistency these industries need.

Specification

Industrial Automatic Emulsion Coating Machine for Screen Printing

The PT-F Automatic Emulsion Coating Machine is ideal for screen printing and textile printing businesses in Bangladesh. It’s perfect for those upgrading from manual coating. The machine delivers full automation, saving labor and ensuring consistent results. It’s a smart investment for any modern textile or graphic printing operation.Product Specification

| Model | PT-G01 | PT-G02 |

| Max frame(Out) | 1000*1100mm | 1600*2400mm |

| Min frame(Out) | 600*600mm | 800*800mm |

| Coating speed | 50~150mm/sec | |

| Frame fixed way | Vacuum fixed clamp | |

| Air pressure | 6kg/c㎡ | |

| Weight | 550kg | 950kg |

| Power | 220V*1ph*450w | 220v*1ph*600w |

| Machine size(W X D X H) | 1920*580*1900mm | 2250*980*3300mm |

Advantage & Features

Advantage & Features

- Automatic Emulsion Coating Machine is equipped with a high-quality imported motor for smooth, vibration-free operation, ensuring a stable and even coating thickness.

- The PLC system allows you to choose single or double-sided coating, either manually or automatically, with real-time adjustments to the applicator speed.

- The robust structure, built from durable stainless steel, provides longevity and features built-in protection systems for safe operation.

- A special pressure system ensures even delicate materials receive a precise coating with the desired thickness.

- The screen holder can be adjusted up or down, making the loading and coating of screens of various sizes simple and efficient.

Applications

Applications

- Textile and Garment Printing: A key part of Bangladesh’s economy, screen printing is essential for t-shirts, fabrics, and ready-made garments. The PT-F Automatic Emulsion Coating Machine ensures precise coating for detailed designs before the screen goes to the printing press.

- Home Textile Industry: For products like bedsheets, curtains, and upholstery, the PT-F Automatic Emulsion Coating Machine helps prepare screens that deliver vibrant, long-lasting prints.

- Promotional and Custom Apparel: With growing demand for custom t-shirts and branded items, the PT-F Automatic Emulsion Coating Machine enables fast and reliable screen prep for quick delivery.

- Industrial and Graphic Screen Printing: The PT-F Automatic Emulsion Coating Machine also supports printing on signage, ceramics, plastics, and electronics—offering the precision and consistency these industries need.

Product Comparison

Product Comparison Table with Similar Products

| Feature | PT-G02 / PT-F02 Automatic Emulsion Coating Machine | ATMA AT-C1216D Automatic Screen Coater |

| Max Frame Size | 1200 x 1600 mm | 1200 x 1600 mm |

| Min Frame Size | 500 x 700 mm | 500 x 700 mm |

| Coating Principle | Pneumatic clamping, special pressure device | Servo motors, quick locking, double-sided coating |

| Control System | PLC Controlled | PLC Controlled, Touch Panel HMI |

| Motor Type | Imported High-Precision Motor | Servo Motor |

| Key Advantage | Cost-effective automation with high consistency | High-end precision, advanced control, quick setup |

| Target Market | Mid to Large-scale operations seeking efficient auto coating | High-end industrial precision screen printing |

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The Automatic Emulsion Coating Machine comes with a service warranty that covers its core electrical components, coating control system, and motorized rail mechanism. Some parts—like coating troughs, rubber seals, and guide wheels—naturally wear out over time and are considered consumables, so they aren’t covered under the warranty. If any covered part stops working during the warranty period, our technicians will handle the repair or replacement, but customers will need to purchase any necessary spare parts. Please note that customers are responsible for all shipping costs when sending or receiving parts or equipment.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including free consultations.

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Product Warranty

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The Automatic Emulsion Coating Machine comes with a service warranty that covers its core electrical components, coating control system, and motorized rail mechanism. Some parts—like coating troughs, rubber seals, and guide wheels—naturally wear out over time and are considered consumables, so they aren’t covered under the warranty. If any covered part stops working during the warranty period, our technicians will handle the repair or replacement, but customers will need to purchase any necessary spare parts. Please note that customers are responsible for all shipping costs when sending or receiving parts or equipment.

Technical & After Sales Service

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including free consultations.

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Company Info

Prominent Tec Company Information

Address: House #9, Block #A, Road #1, Niketon, Dhaka-1212, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.

Q1: What is the PT-F Automatic Emulsion Machine and why is it important?

It’s an auto coater that evenly spreads emulsion on screens—crucial for consistent, high-quality screen printing in Bangladesh. It replaces manual work, boosts speed, and reduces errors with a plc set single double-sided coated feature.

Q2: How does it improve print quality?

The PT-F Automatic Emulsion Coating Machine ensures smooth coating, preventing pinholes or ink smudges. That means sharper prints, better color accuracy, and improved output on garments and other materials.

Q3: What frame sizes can it handle?

Models like PT-F01 support frames from 600×600mm to 1000×1100mm. Larger models go up to 1600×2400mm, fitting a wide range of printing needs.

Q4: Is it hard to operate?

Not at all. The machine has a PLC system with manual or auto modes. You can set single or double-sided coating. Training is provided to get your team up to speed quickly.

Q5: What are the power and air requirements?

Standard industrial setup—220V, single phase, 450W, and 6 kg/c㎡ air pressure.

Q6: Can it use different photoemulsions?

Yes. The adjustable applicator and pressure system handle various emulsion types and thicknesses with ease.

Q7: What maintenance does it need?

Regular cleaning of the head and frame area, checking moving parts, and lubrication to maintain optimal speed of the sizing. Prominent Tec offers lifetime maintenance support.

Q8: Where can I get spare parts locally?

Basic parts like fittings or sensors can be sourced from industrial shops in Bangladesh. For PT-specific parts, go through official distributors.