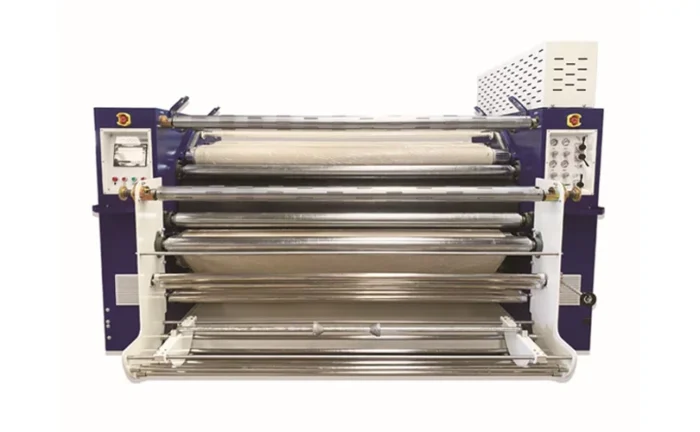

Sublimation Heat Transfer Printing Machine for High-Quality Textile & Garment Printing

Unleash vibrant, durable designs with the PT-DP10 Roller Sublimation Heat Transfer Machine, engineered for high-volume textile and apparel production in Bangladesh.

- Model name: PT-DP10

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months

- Packaging: Standard Export Wooden Case

Share:

Request a quote for

Sublimation Heat Transfer Printing Machine for High-Quality Textile & Garment Printing

Unleash vibrant, durable designs with the PT-DP10 Roller Sublimation Heat Transfer Machine, engineered for high-volume textile and apparel production in Bangladesh.

- Model name: PT-DP10

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months

- Packaging: Standard Export Wooden Case

Share:

Product Info

Sublimation Heat Transfer Machine

This industrial-grade heat press utilizes advanced oil heating for consistent, uniform heat transfer printing, making it ideal for sportswear, fashion fabrics, and other textile printing. Experience efficient, precise sublimation with roll-to-roll capabilities, ensuring your designs come to life with exceptional clarity and color.Product Specification

| Model | 1m | 800mm | 600mm | 600mm plus | 420mm | 270mm | 200mm |

| voltage V | 380 | 380 | 380 | 380 | 380 | 380 | 220 |

| frequency Hz | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Power kw | 90 | 65 | 50 | 50 | 23 | 16 | 7 |

| Drum diameter mm | 1000 | 800 | 600 | 600 | 420 | 270 | 200 |

| Wide of Roller mm | 2080 | 2080 | 1860 | 2060 | 1860 | 1860 | 1200 |

| Blanket mm | 1950 | 1950 | 1730 | 1950 | 1730 | 1730 | 1150 |

| Transfer printing width mm | 1900 | 1900 | 1700 | 1900 | 1700 | 1700 | 1050 |

| Working Table area mm | Length customized×2000w | Length customized×2000w | 3000L×1780W | 3000L×1980W | 1510L×1780W | 2000L×1810W | 1000L×1280W |

| Heating | oil heating | oil heating | oil heating | oil heating | oil heating | oil heating | oil heating |

| Max running speed m/h | 900 | 500 | 230 | 230 | 180 | 100 | 70 |

| Transfer speed m/h | 500 | 300 | 150 | 150 | 120 | 60 | 40 |

| N.W kg | 4500 | 3500 | 2000 | 2400 | 1500 | 1000 | 400 |

| Packing Sizes mm | 3100*2500*2500 | 2900×2000×2000 | 2640×1750×1910 | 2640×1750×1910 | 2640×1600×1910 | 2680×950×1480 | 1810×800×1410 |

| Power Configuration | Three-phase four-wire | Three-phase four-wire | Three-phase four-wire | Three-phase four-wire | Three-phase four-wire | Three-phase four-wire | single phase |

Advantage & Features

Features of the Roller Sublimation Heat Transfer Machine:

- Includes an automatic blanket correction feature for optimal performance with a heat press machine.

- Equipped with dual air expansion shafts, ideal for handling sublimation paper in a press machine.

- The 800mm diameter drum achieves a 70% blanket coverage rate, with a printing speed of 600–700 meters per hour, making it perfect for roll to roll heat applications.

- Built-in digital delay switch display helps reduce manual effort during heat press transfer operations.

-

The inverter system detects faults and halts operation to prevent blanket damage, ensuring the reliability of your roller heat press.

Applications

The PT-DP10 Roller Sublimation Heat Transfer Machine is highly versatile and widely used across sectors in Bangladesh:

- Apparel Manufacturing: Ideal for sportswear, fashion, and casual wear with vibrant, durable prints—key for Bangladesh’s RMG sector.

- Soft Signage & Display Graphics: Produces colorful flags, banners, and backdrops for events, retail, and outdoor ads.

- Home Furnishings: Prints on curtains, bed covers, cushions, and other decor items for mass or custom production.

- Promotional Products: Enables custom printing on bags, lanyards, and fabric-based promo items.

-

Technical Textiles: Used for branded or patterned textiles in automotive and industrial applications.

Specification

Sublimation Heat Transfer Machine

This industrial-grade heat press utilizes advanced oil heating for consistent, uniform heat transfer printing, making it ideal for sportswear, fashion fabrics, and other textile printing. Experience efficient, precise sublimation with roll-to-roll capabilities, ensuring your designs come to life with exceptional clarity and color.Product Specification

| Model | 1m | 800mm | 600mm | 600mm plus | 420mm | 270mm | 200mm |

| voltage V | 380 | 380 | 380 | 380 | 380 | 380 | 220 |

| frequency Hz | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Power kw | 90 | 65 | 50 | 50 | 23 | 16 | 7 |

| Drum diameter mm | 1000 | 800 | 600 | 600 | 420 | 270 | 200 |

| Wide of Roller mm | 2080 | 2080 | 1860 | 2060 | 1860 | 1860 | 1200 |

| Blanket mm | 1950 | 1950 | 1730 | 1950 | 1730 | 1730 | 1150 |

| Transfer printing width mm | 1900 | 1900 | 1700 | 1900 | 1700 | 1700 | 1050 |

| Working Table area mm | Length customized×2000w | Length customized×2000w | 3000L×1780W | 3000L×1980W | 1510L×1780W | 2000L×1810W | 1000L×1280W |

| Heating | oil heating | oil heating | oil heating | oil heating | oil heating | oil heating | oil heating |

| Max running speed m/h | 900 | 500 | 230 | 230 | 180 | 100 | 70 |

| Transfer speed m/h | 500 | 300 | 150 | 150 | 120 | 60 | 40 |

| N.W kg | 4500 | 3500 | 2000 | 2400 | 1500 | 1000 | 400 |

| Packing Sizes mm | 3100*2500*2500 | 2900×2000×2000 | 2640×1750×1910 | 2640×1750×1910 | 2640×1600×1910 | 2680×950×1480 | 1810×800×1410 |

| Power Configuration | Three-phase four-wire | Three-phase four-wire | Three-phase four-wire | Three-phase four-wire | Three-phase four-wire | Three-phase four-wire | single phase |

Advantage & Features

Advantage & Features

Features of the Roller Sublimation Heat Transfer Machine:

- Includes an automatic blanket correction feature for optimal performance with a heat press machine.

- Equipped with dual air expansion shafts, ideal for handling sublimation paper in a press machine.

- The 800mm diameter drum achieves a 70% blanket coverage rate, with a printing speed of 600–700 meters per hour, making it perfect for roll to roll heat applications.

- Built-in digital delay switch display helps reduce manual effort during heat press transfer operations.

-

The inverter system detects faults and halts operation to prevent blanket damage, ensuring the reliability of your roller heat press.

Applications

Applications

The PT-DP10 Roller Sublimation Heat Transfer Machine is highly versatile and widely used across sectors in Bangladesh:

- Apparel Manufacturing: Ideal for sportswear, fashion, and casual wear with vibrant, durable prints—key for Bangladesh’s RMG sector.

- Soft Signage & Display Graphics: Produces colorful flags, banners, and backdrops for events, retail, and outdoor ads.

- Home Furnishings: Prints on curtains, bed covers, cushions, and other decor items for mass or custom production.

- Promotional Products: Enables custom printing on bags, lanyards, and fabric-based promo items.

-

Technical Textiles: Used for branded or patterned textiles in automotive and industrial applications.

Product Comparison

Product Comparison Table with Similar Products

| Feature | PT-DP10 (Manufacturer Specs) | Heatertex HT07525P (Bangladesh Market) | Y-jet (DBX Series – Bangladesh Market) |

| Key Advantage | Wide range of drum sizes, high blanket wrapping rate (HJD 800mm), robust build. | Advanced PLC/touch screen control, automation features, proven European design. | Full oil drum design for stability, high speed, roll-to-roll & piece-by-piece. |

| Heating Method | Oil Heating | Thermal Oil | Oil, 100% full drum |

| Drum Diameter | 200mm – 1000mm (various models) | 650mm (25″) | 420mm, 600mm, 800mm (DBX-1200B/1700B/1900B) |

| Max Transfer Width | Up to 1900mm (for larger models) | Approx. 1850mm (72″) | Up to 3200mm (DBX-3200B) |

| Max Speed (m/min) | Up to 8.3 m/min (500 m/h for 1000mm drum) | 1-5 m/min | 2-3 m/min (transfer paper/offset paper) |

| Control System | Digital display, Inverter, Auto-correction | PLC, Touch Screen, Auto blanket position, Pneumatic tension system | Precise temperature control, auto blanket aligning, external oil tank |

| Power (kW) | 7 kW – 90 kW (model dependent) | 36 kW | 15 kW – 40 kW (model dependent) |

| Transfer System | Roll-to-roll (implied by design) | Roll-to-roll and Piece-by-piece | Roll-to-roll and Piece-by-piece |

| Warranty | 1 Year (Manufacturer) | 1 Year | 1 Year |

| Estimated Landed Cost in Bangladesh | BDT 20-50 Lakh+ (Estimated, depending on model, FOB price, import duties ~20-25%, and shipping) | BDT 25-60 Lakh+ (Estimated, given similar class) | BDT 13.95 Lakh (for smaller Y-jet model like BA42170) – 50 Lakh+ (larger models) |

| Typical Applications | Apparel, Soft Signage, Home Furnishings | Dresses, Flags, Curtains, Footwear, Banners | Garment Shops, Manufacturing Plants, Printing Shops, T-shirts, Sportswear |

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The PT-DP10 Roller Sublimation Heat Transfer Printing Machine comes with a service warranty that covers its main electrical components, roller heating system, and digital control panel. Some items—like transfer paper rollers, silicone blankets, and heating elements—naturally wear out over time and are considered consumables, so they aren’t covered under the warranty. If any covered part stops working during the warranty period, our technicians will handle the repair or replacement, but customers will need to purchase any necessary spare parts. Please note that customers are responsible for all shipping costs when sending or receiving parts or equipment.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Product Warranty

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The PT-DP10 Roller Sublimation Heat Transfer Printing Machine comes with a service warranty that covers its main electrical components, roller heating system, and digital control panel. Some items—like transfer paper rollers, silicone blankets, and heating elements—naturally wear out over time and are considered consumables, so they aren’t covered under the warranty. If any covered part stops working during the warranty period, our technicians will handle the repair or replacement, but customers will need to purchase any necessary spare parts. Please note that customers are responsible for all shipping costs when sending or receiving parts or equipment.

Technical & After Sales Service

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Company Info

Prominent Tec Company Information

Address: House #9, Block #A, Road #1, Niketon, Dhaka-1212, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.

What materials can the PT-DP10 Roller Sublimation Heat Transfer Machine print on?

It prints on polyester and polyester-blend fabrics using sublimation inks for vibrant, long-lasting results.

How does oil heating compare to electric heating in a roller sublimation heat press?

Oil heating gives more stable, even heat, preferred for high-quality, continuous roll printing.

Is sublimation printing environmentally friendly?

Yes, it saves water, energy, and chemicals, though broader industry practices still raise environmental concerns.

What is sublimation heat transfer?

Sublimation heat transfer is a printing process that uses heat to transfer dye onto materials, typically fabrics.

Can you use heat transfer paper for sublimation?

No, heat transfer paper is not suitable for sublimation. Sublimation requires special sublimation paper that allows the dye to penetrate the material when heated.

Does this product support customization?

Yes, many sublimation heat transfer machines support customization, allowing users to create unique designs tailored to their specific needs.

Is sublimation a profitable business?

Yes, sublimation can be a profitable business due to its low startup costs and high demand for customized products.

Can you use heat transfer paper for sublimation?

No, sublimation requires special sublimation paper, not regular heat transfer paper.

Does this product support customization?

Yes, many sublimation heat transfer machines support customization options.

Is local service and support available for this Sublimation Heat Transfer Machine?

Yes, Prominent Tec in Bangladesh offers installation, training, service, and spare parts.