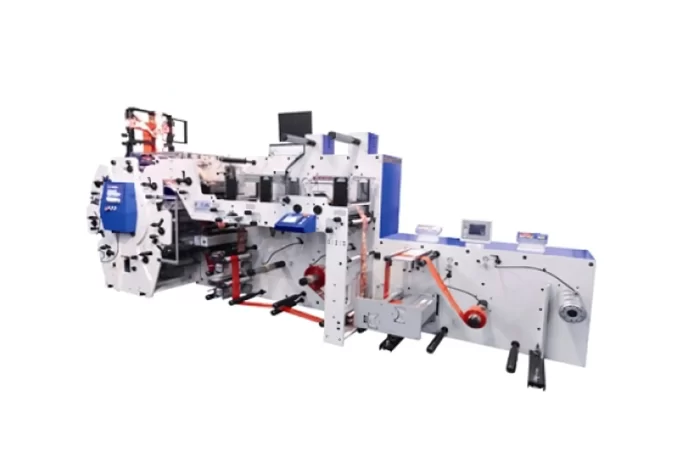

Centraflex – Central Impression Flexo Press for High-Quality Label & Film Printing

Experience unparalleled printing precision with the Centraflex CI Flexo printing press, designed for high print quality on demanding substrates. Engineered in the UK by Focus Label Machinery, the Centraflex is the definitive solution for Bangladeshi businesses demanding superior quality on flexible packaging, films, and labels.

- Model name: PT

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months

- Packaging: Standard Export Wooden Case

Share:

Request a quote for

Centraflex – Central Impression Flexo Press for High-Quality Label & Film Printing

Experience unparalleled printing precision with the Centraflex CI Flexo printing press, designed for high print quality on demanding substrates. Engineered in the UK by Focus Label Machinery, the Centraflex is the definitive solution for Bangladeshi businesses demanding superior quality on flexible packaging, films, and labels.

- Model name: PT

- Payment Method: L/C at Sight or T/T in Advance

- Min. Order: 01

- Warranty: 12 Months

- Packaging: Standard Export Wooden Case

Share:

Product Info

Centraflex

This compact and versatile narrow web label press machine utilizes Central Impression (CI) technology to guarantee perfect print registration and vibrant results. Elevate your production capabilities and achieve a competitive edge, making quality a priority the centraflex makes possible for modern manufacturers.Product Specification

| Model | CENTRAFLEX 250/330 | CENTRAFLEX 250/330 U.V |

| Number of Colours | 5 + 1 | 6 + 1 |

| Max Print Width | 10”(254mm)/13”(330mm) | 10”(254mm)/13”(330mm) |

| Print range | 7-20” (188-510mm) | 10”-20” (254mm-510mm) |

| IR Drying | Standard | Optional |

| UV Drying | 1 Optional | Standard |

| Chill Drum | Optional | Standard |

| Rotary Die Cutting | Optional | Optional |

| Rotary Slitting | Optional | Optional |

| Max Unwind Diameter | 650mm (Std) 1000mm(Optional) | 1000mm (Std) |

| Max Rewind Diameter | 600mm(22”) | 600mm(22”) |

| Other Options | Turn Bar, Cold Foil, Lamination ,Rotary Cutting/Slitting, Sheet Stacker Web Cleaner, Corona Treater, Video Inspection. Double Unwind, Double Rewind, Static control | |

Advantage & Features

- New press design available in 5+1 or 6+1 color configurations

- Delivers excellent registration and print quality, even on unsupported web materials

- Supports both UV and IR drying systems

- Equipped with a chilled central impression drum

- Compact design ideal for efficient converting operations

Applications

The Centraflex is ideally suited to serve the primary industrial sectors of Bangladesh.

- Garment & Apparel Packaging: Produce high-quality, branded poly bags, hang tags, and riders for the export-oriented RMG sector. The machine’s precision on PE and PP films ensures brand standards are met.

- Food & Beverage Flexible Packaging: Print stunning and safe pouches, sachets, snack wrappers, and labels. The Centraflex is compatible with food-grade inks and processes like reverse printing to comply with BFSA regulations.

- Pharmaceutical Labels & Packaging: Achieve the highest level of precision required for printing on blister foils, medical-grade paper, and labels, ensuring all text and barcodes are perfectly legible and compliant.

- General Label & Ticket Production: A highly efficient label press machine for producing high volumes of self-adhesive labels and event or transit ticket products for consumer goods, industrial products, and more.

Specification

Centraflex

This compact and versatile narrow web label press machine utilizes Central Impression (CI) technology to guarantee perfect print registration and vibrant results. Elevate your production capabilities and achieve a competitive edge, making quality a priority the centraflex makes possible for modern manufacturers.Product Specification

| Model | CENTRAFLEX 250/330 | CENTRAFLEX 250/330 U.V |

| Number of Colours | 5 + 1 | 6 + 1 |

| Max Print Width | 10”(254mm)/13”(330mm) | 10”(254mm)/13”(330mm) |

| Print range | 7-20” (188-510mm) | 10”-20” (254mm-510mm) |

| IR Drying | Standard | Optional |

| UV Drying | 1 Optional | Standard |

| Chill Drum | Optional | Standard |

| Rotary Die Cutting | Optional | Optional |

| Rotary Slitting | Optional | Optional |

| Max Unwind Diameter | 650mm (Std) 1000mm(Optional) | 1000mm (Std) |

| Max Rewind Diameter | 600mm(22”) | 600mm(22”) |

| Other Options | Turn Bar, Cold Foil, Lamination ,Rotary Cutting/Slitting, Sheet Stacker Web Cleaner, Corona Treater, Video Inspection. Double Unwind, Double Rewind, Static control | |

Advantage & Features

Advantage & Features

- New press design available in 5+1 or 6+1 color configurations

- Delivers excellent registration and print quality, even on unsupported web materials

- Supports both UV and IR drying systems

- Equipped with a chilled central impression drum

- Compact design ideal for efficient converting operations

Applications

Applications

The Centraflex is ideally suited to serve the primary industrial sectors of Bangladesh.

- Garment & Apparel Packaging: Produce high-quality, branded poly bags, hang tags, and riders for the export-oriented RMG sector. The machine’s precision on PE and PP films ensures brand standards are met.

- Food & Beverage Flexible Packaging: Print stunning and safe pouches, sachets, snack wrappers, and labels. The Centraflex is compatible with food-grade inks and processes like reverse printing to comply with BFSA regulations.

- Pharmaceutical Labels & Packaging: Achieve the highest level of precision required for printing on blister foils, medical-grade paper, and labels, ensuring all text and barcodes are perfectly legible and compliant.

- General Label & Ticket Production: A highly efficient label press machine for producing high volumes of self-adhesive labels and event or transit ticket products for consumer goods, industrial products, and more.

Product Comparison

Product Comparison Table with Similar Products

| Feature | Focus Centraflex | Typical Inline Flexo Press | Typical Rotogravure Press |

| Core Technology | Central Impression (CI) Flexo | Independent Print Stations | Engraved Cylinders |

| Registration on Films | Excellent | Fair to Good | Good |

| Ideal Run Length | Short to Long | Short to Medium | Very Long |

| Setup & Changeover | Moderate | Fast | Slow & Costly |

| Plate/Cylinder Cost | Low to Moderate | Low | Very High |

| Substrate Flexibility | Very High | High | Moderate |

| Best For | High-quality flexible packaging, labels, and versatile production needs. | Quick setup labels and basic film printing. | Extremely high-volume, single-design packaging runs. |

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The Centraflex comes with a service warranty that covers essential press components including the central impression drum, servo control systems, and electronic drive modules. Some items—like ink pumps, doctor blades, print sleeves, and other wear-sensitive parts—naturally wear out over time and are considered consumables, so they aren’t covered under the warranty. If any covered part stops working during the warranty period, our technicians will handle the repair or replacement, but customers will need to purchase any necessary spare parts. Please note that customers are responsible for all shipping costs when sending or receiving parts or equipment.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Product Warranty

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The Centraflex comes with a service warranty that covers essential press components including the central impression drum, servo control systems, and electronic drive modules. Some items—like ink pumps, doctor blades, print sleeves, and other wear-sensitive parts—naturally wear out over time and are considered consumables, so they aren’t covered under the warranty. If any covered part stops working during the warranty period, our technicians will handle the repair or replacement, but customers will need to purchase any necessary spare parts. Please note that customers are responsible for all shipping costs when sending or receiving parts or equipment.

Technical & After Sales Service

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Company Info

Prominent Tec Company Information

Address: House #9, Block #A, Road #1, Niketon, Dhaka-1212, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.

Q1: What makes the Centraflex the best choice for printing on flexible films in Bangladesh?

A1: The CI drum on this centraflex machine prevents film distortion, ensuring sharp registration. This is ideal for poly bags and flexible packaging, especially when using equipment where the machines are central impression flexographic by design.

Q2: Is local service and support available for this Centraflex?

A2: Yes, Prominent Tec in Bangladesh offers installation, training, service, and spare parts.

Q3: How does this label press machine compare to an inline flexo press?

A3: Centraflex delivers better registration, quality, and material versatility—making it more advanced and future-ready.

Q4: What types of inks can I use with the Centraflex?

A4: It supports water-based, solvent-based, and UV inks, depending on the chosen drying system.

Q5: Is the Centraflex a cost-effective solution?

A5: Yes, it offers fast setup, low waste, high speed, and handles diverse jobs—ensuring strong ROI and lower costs.