Eco-Friendly Heat Transfer Hydrochromic Ink – Reversible Color Change Effect

Elevate your textile production with our premium heat transfer water based hydrochromic ink.

| Model name |

PT |

|---|---|

| Payment Method |

Stripe, Paypal |

| Min. Order |

5 KG |

| For Import Min QTY |

300 KG. |

Heat Transfer Water Based Hydrochromic Ink

Engineered for the modern Bangladesh RMG export market, this high-performance hydrochromic ink for fabric is a specialized product within professional inks & consumables, creating dynamic “wet-and-reveal” effects by turning opaque white when dry and transparent when wet. Fully compliant with ZDHC and Oeko-Tex standards, it offers the perfect solution for high-value swimwear and activewear branding.

Product Specification

| Specification | Details |

| Ink Type | Water based hydrochromic ink |

| Appearance | White color ink when it gets dry |

| Viscosity | 30,000 – 40,000 mPa-s (Thixotropic) |

| Screen board suggestion | 100 – 150 Mesh |

| Peel Type | Cold Peel Only (to prevent ink splitting) |

| Compliance | ZDHC Level 3, Oeko-Tex Standard 100, PVC-Free |

Advantage & Features

- Eco-friendly

- Strong tack strength

- High opacity

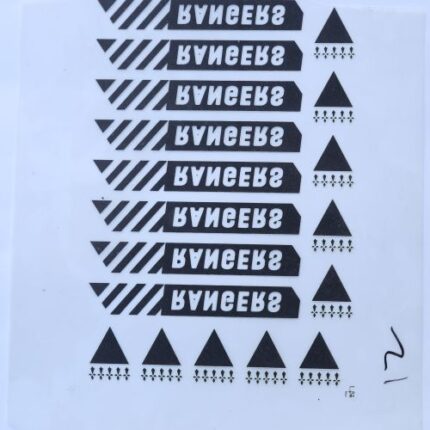

- The white print becomes transparent when exposed to water and returns to white once dry — a reversible, moisture-dependent color change

- Suitable for creative or decorative designs

Applications

This versatile hydrochromic ink for fabric is widely used in high-value textile sectors:

- Swimwear & Beachwear: Reveal patterns or logos when the wearer enters the water.

- Smart Activewear: Function as a sweat indicator, signaling when an athlete needs hydration.

- Medical Textiles: Use as moisture indicators for wound dressings or hygiene products.

- Promotional Items: Umbrellas and rainwear that change design in the rain.

Product Comparison Table with Similar Products

| Feature | Water-Based Hydrochromic Ink (Our Product) | Plastisol Hydrochromic | Solvent-Based Hydrochromic |

| Eco-Compliance | Excellent. ZDHC/Oeko-Tex Compliant. | Poor. Contains PVC/Phthalates. | Very Poor. High VOC emissions. |

| Hand Feel | Soft & Breathable. Ideal for activewear. | Heavy/Plastic. “Sweat patch” effect. | Stiff. Often feels like paper. |

| Primary Solvent | Water (H2O) | Plasticizers | Organic Solvents |

| Market Suitability | Export Market (EU/USA) | Domestic/Local Market | Industrial/Non-wearables |

Delivery Time

45-60 days. Please contact our sales team for precise delivery estimates for machine purchases.

Q: What mesh count should I use for water based hydrochromic ink?

A: Use 80–120 mesh (32T–48T). Lower mesh builds a thicker, opaque layer to fully hide the image when dry.

Q: Why is my print ghosting (showing the hidden image when dry)?

A: The ink layer is too thin, which affects the quality of the final print. Use a lower mesh or add a Print-Flash-Print stroke to increase opacity.

Q: Is this water based hydrochromic ink compatible with nylon swimwear?

A: Yes, but use Polyamide (PA) hot-melt powder for nylon. For cotton, use PU powder.

Q: Can I peel the transfer while it’s hot?

A: No. It requires a Cold Peel. Hot peeling can cause the ink to split or lift, impacting the overall quality of the printed material.

Q: Does this ink need a fixing agent?

A: Yes, add 1–3% fixing agent for durability and wash fastness—especially important in humid climates to prevent hydrolysis.

Prominent Tec Company Information

Address: House No. 99, Lift No. 07, Rd No. 4, Block B, Banani, Dhaka-1213, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.