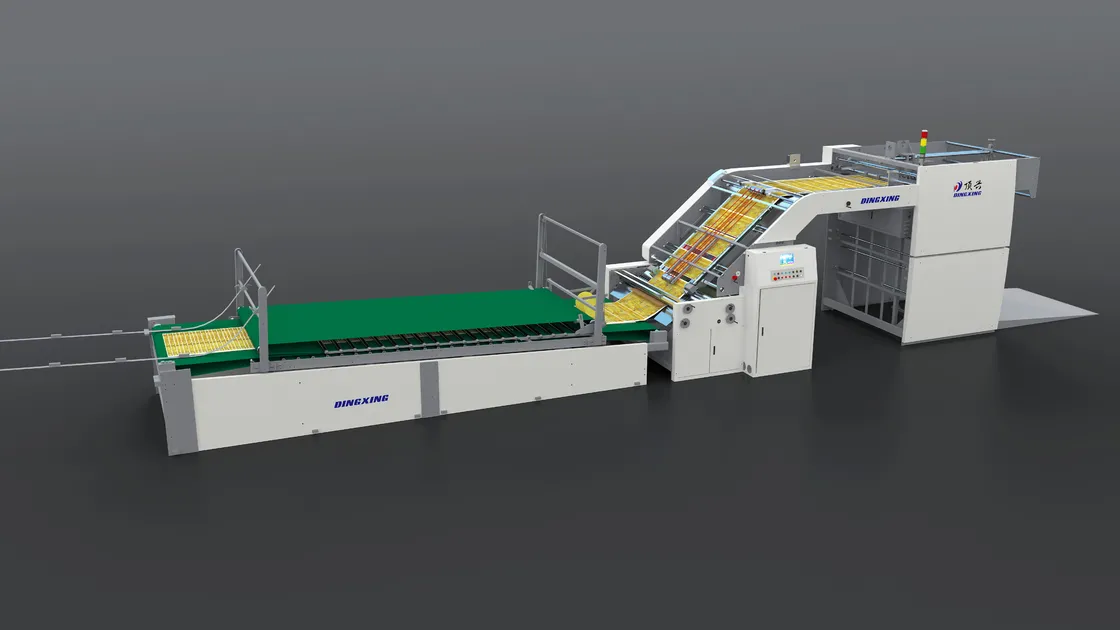

High-Speed Big Size Flute Laminator Machine | Automatic Precision Laminating Solution

Achieve premium, high-strength packaging with our advanced Flute Laminator Machine. This fully automatic high speed flute laminator is engineered for perfect sheet-to-sheet lamination, bonding offset printed top sheets to corrugated bottom sheets with unmatched precision.

| Model name |

FKT-DX1450 |

|---|---|

| Payment Method: |

L/C at sight or T/T in advance |

| Min. Order |

01 |

| Warranty |

12 Months. |

| Packaging |

Standard Export Wooden Case |

Flute Laminator high speed big size

Ideal for high-volume production, this flute laminator machine functions as a reliable packaging machine that boosts your efficiency, reduces waste, and delivers the superior structural and graphic quality your clients demand.

Product Specification

| S/L | Source Feature/Finding | Customer Requirement |

| 01 | Max. Sheet Size (W*L): 1450*1450mm Min. Sheet Size (W*L): 450*450mm Top sheet thicnkess: 120~600gsm Bottom sheet thickness: 0.5-10mm Laminating Accuracy: ±1mm (subject to paper cutting precision) Max. Speed: 150 m/min (Subject to board quality and specification) e.g. around 10,000 sheets/hour at length 600mm Power: 25kw Dimension L*W*H: 14056*2314*2560mm | Flute Laminator |

Advantage & Features

- Servo Shaftless Back Feeder: This servo-controlled shaftless feeder allows the top sheet to overlap during feeding, making the process faster, smoother, and more efficient.

- Dual Servo Bottom Sheet Feeder: Two servo motors work together to ensure stable feeding, even when using warped or multi-layer paperboards.

- High-Speed Computerized Lamination: The system can laminate up to Max. Speed: 150 m/min (Subject to board quality and specification) around 10,000 sheets/hour at length 600mm providing both speed and precision in large-scale production.

- Feeder Base Design: The low E-type piling table allows direct paper loading with a pallet cart, making setup quick and easy. An optional railway truck pre-loader is also available for higher productivity.

- Advanced Gluing System: Features high-precision glue rollers, a glue side stopper, and an automatic glue level controller. The glue recirculation system prevents overflow, ensuring clean and consistent application even at high speeds.

- Smart Alignment System: Multiple sensors track the bottom sheet’s position, while servo motors automatically adjust the top sheet for perfect alignment — ensuring every layer is accurately placed.

- lectrical Control System: Comes with a user-friendly Human-Machine Interface (HMI) powered by PLC control. It includes warning indicators, automatic fault detection, and production monitoring. The system is CE certified, ensuring safety, reliability, and compliance with international standards.

Applications

This automatic high speed flute laminator is an essential asset for any packaging converter focused on high-quality litho-lamination. The capabilities of this flute laminator machine are ideal for producing:

- Premium Retail Packaging: This flute laminator machine is perfect for creating stunning, durable boxes for electronics, cosmetics, and luxury goods where graphic appeal is paramount.

- Point-of-Sale (POS) Displays: Manufacturing robust and visually striking floor displays, counter stands, and signage. Our automatic high speed flute laminator excels at this.

- Food & Beverage Packaging: Producing strong, high-graphic boxes for food trays, beverage carriers, and bulk-goods containers.

- E-commerce & Subscription Boxes: Upgrading standard brown boxes to full-color, branded mailers that enhance the unboxing experience.

- Toy & Game Boxes: The precision of our flute laminator machine ensures the rigid, perfect boxes required for the toy industry.

Product Comparison Table with Similar Products

| Feature | Our Flute Laminator Machine (FL-1450) | Competitor Model A | Competitor Model B |

| Control System | Full Servo PLC | Manual / Photocell | Full Servo PLC |

| Max Speed | 10,000 sheets/hour | 4,000 sheets/hour | 12,000 sheets/hour |

| Alignment Precision | ± 1.0 mm | ± 2.5 mm | ± 0.5 mm |

| Setup Time | Fast (15-20 min) | Slow (45-60 min) | Very Fast (10-15 min) |

| Key Description | automatic high speed flute laminator | flute laminator | high-speed laminator / flute laminator machine |

Warranty Period: 12 Months.

Warranty Terms: The FKT-DX1450 Flute Laminator High Speed Big Size comes with a service warranty that covers technical malfunctions and performance issues related to the machine’s core laminating and alignment functions. Certain components—such as belts, rollers, bearings, and other consumable parts—are subject to natural wear and tear and are therefore not covered under this warranty. If any covered part experiences a malfunction within the warranty period, our certified technicians will provide the necessary repair or replacement service. However, customers will be responsible for purchasing any required spare parts. Please note that all shipping and transportation costs associated with sending or receiving parts or equipment remain the responsibility of the customer.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Q: What is a flute laminator machine?

A: It glues a printed sheet onto a corrugated board, combining strength with high-quality printing.

Q: What makes it an automatic high speed flute laminator machine?

A: It’s fully automated with PLC control, running up to 10,000 sheets per hour.

Q: What glue does it use?

A: It uses PVA or other water-based cold adhesives.

Q: Can it laminate cardboard-to-cardboard?

A: Yes, it also supports cardboard or paperboard lamination.

Prominent Tec Company Information

Address: House No. 99, Lift No. 07, Rd No. 4, Block B, Banani, Dhaka-1213, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.