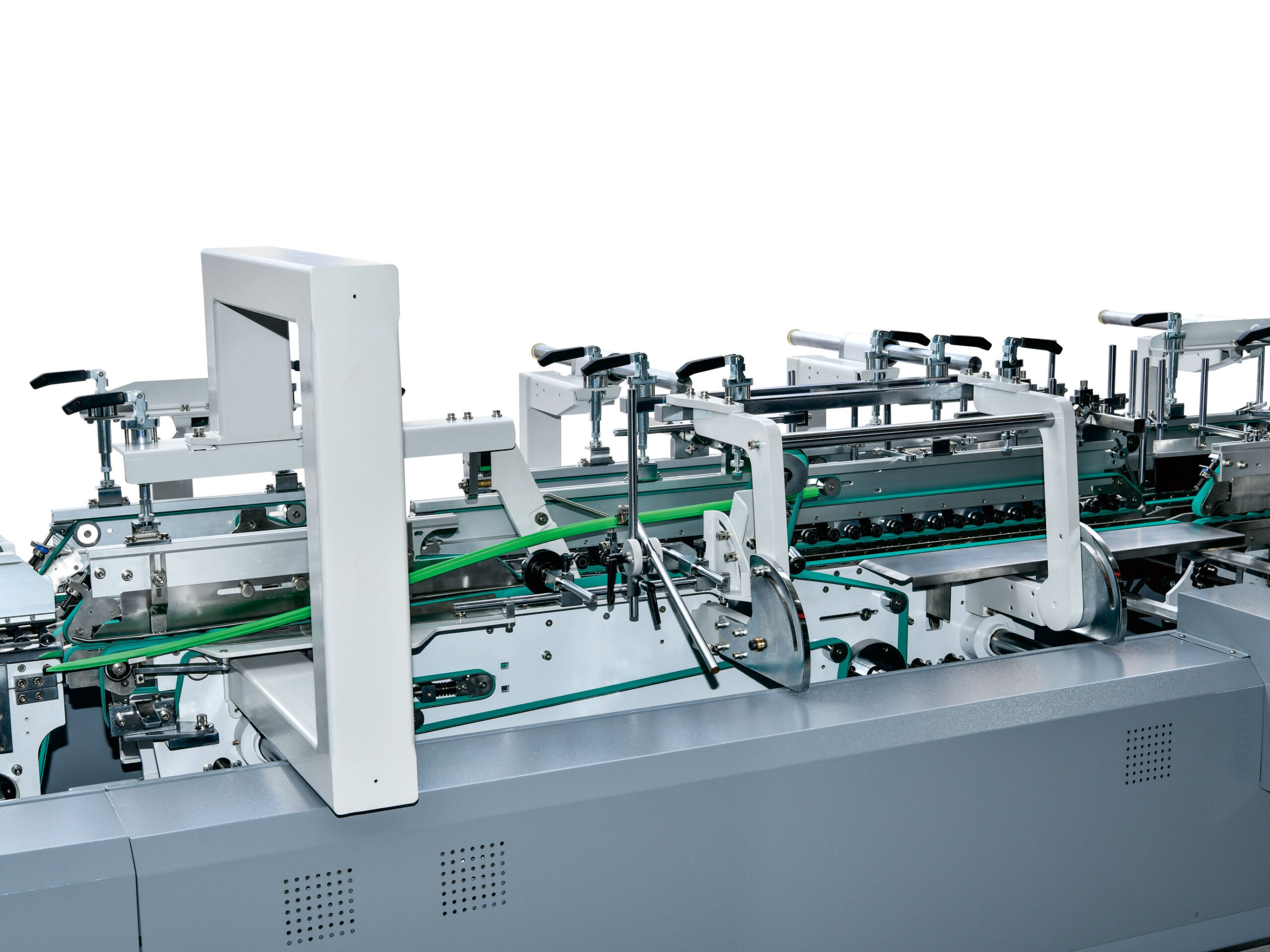

High-Speed Automatic Multi Function Folder Gluer for Carton Packaging

The JY-1100SG multi function folder gluer is engineered to transform manufacturing efficiency, offering a strategic response to the economic pressures in the Bangladesh packaging sector.

| Model name |

JY-1100SG |

|---|---|

| Payment Method |

L/C at sight or T/T in advance |

| Min. Order |

01 |

| Warranty |

12 Months. |

| Packaging |

Standard Export Wooden Case |

Multi function Folder Gluer

The Multi function Folder Gluer is engineered to guarantee consistent, zero-defect quality while minimizing material wastage in high-volume packaging operations. This automatic Multi function Folder Gluer functions as a high-performance packaging machine that helps offset the impact of industrial electricity tariffs and the high Total Tax Incidence (TTI) on imports in Bangladesh. Acting as the final quality assurance stage, the Multi function Folder Gluer plays a critical role in ensuring operational success and production efficiency.

Product Specification

| Specification | Details |

| Material: | Cardboard, Color box, E.F.N flute corrugated board |

| Paper thickness: | 200-800g/m² |

| Speed Max.: | 400m/min |

| Straight line box width: | 140-1100mm |

| Straight line box length: | 100-780mm |

| Lock bottom box width: | 200-1000mm |

| Lock bottom box length: | 120-780mm |

| Feed way: | Automatic continuous feeding |

| Machine size: | L15800 *W1800* H1500mm |

| Power: | 27kW |

| Weight: | ≤10T |

Advantage & Features

Paper Feeding Section

-

Servo motor independently controls the gearbox for precise feeding in the Multi function Folder Gluer.

-

Feeding knife made of tungsten steel for non-abrasive durability.

-

Feeding knife mounted on a linear guide rail for high-precision adjustment.

-

Display screen and camera for real-time monitoring.

-

Three adjustable paper feed knives for flexible feeding control.

-

Special vibration motor ensures smooth, stable feeding.

-

High-precision hexagonal drive shaft for stable operation.

-

Large color display allows rear-end feeding visibility.

Alignment Section

-

Corrects paper skew to improve box accuracy.

-

Left and right alignment mechanisms included.

-

Premium Nita-brand conveyor belts imported from Japan.

-

Two remote controllers replace conventional mechanical control panels.

Pre-Folding Section

-

Long-distance pre-folding allows first fold at 180° and third fold at 135° for easy box opening.

-

Imported folding conveyor belts and low-noise transmission system.

-

Segmentable top plates enable flexibility for custom box designs.

-

Extended multifunction structure supports special-shaped box installation.

-

Three electronic universal remote controllers included.

Bottom Hook Gluing Section

-

Modular aluminum profile structure allows fast setup and easy part replacement.

-

Four high-speed spring hooks for reliable crash-lock bottom forming.

-

Imported folding conveyor belts and multifunction folding knives on both sides.

-

Segmentable top plates enable custom folding operations.

-

Dual-shaft transmission with secondary correction for superior accuracy.

Lower Gluing Section

-

Precision bottom glue tank ensures clean, waste-free gluing at high speed.

-

Dual gluing rollers on left and right sides for quick adjustment.

-

Remote-controlled operation improves efficiency.

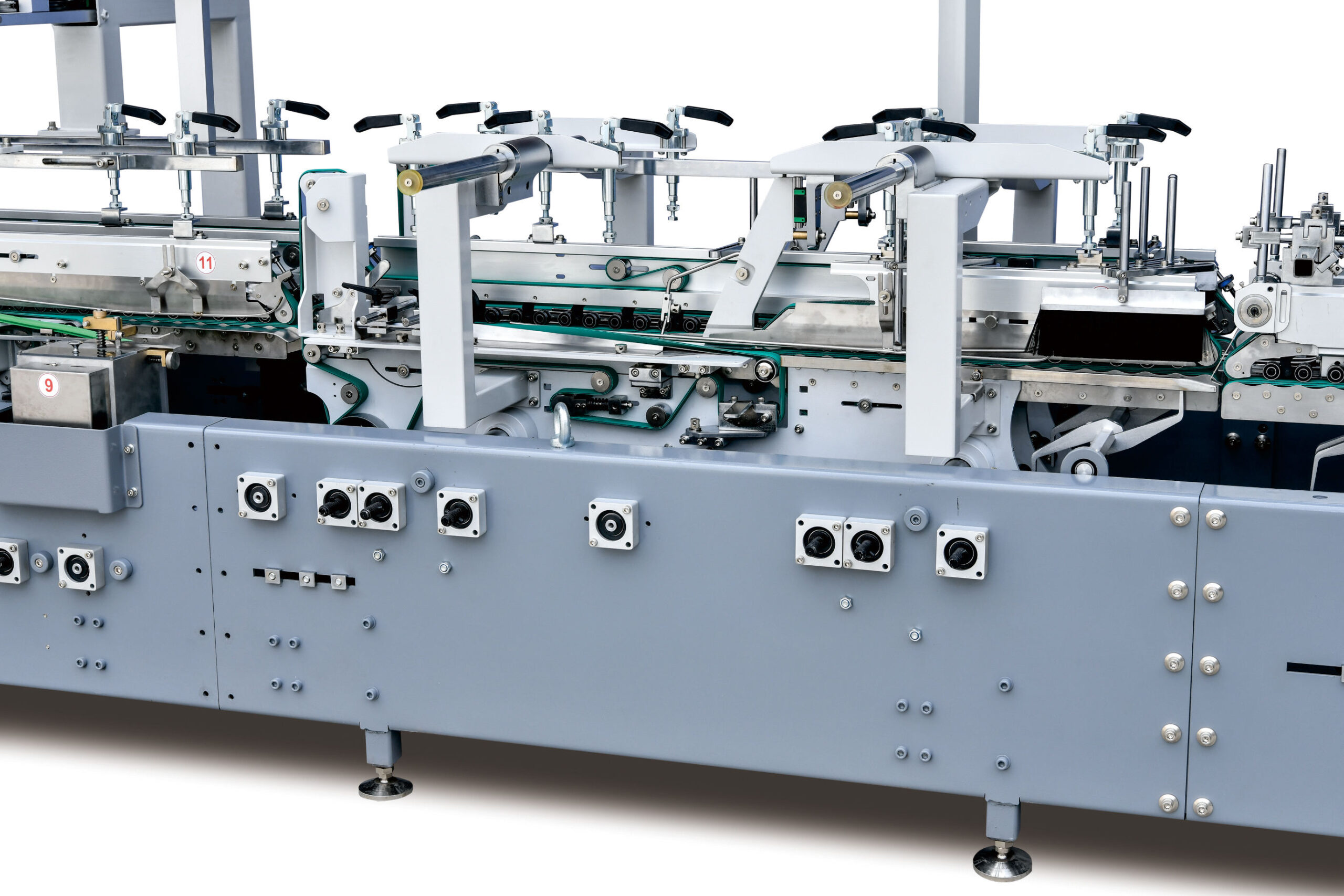

Folding Section

-

Asynchronous servo precision gearbox ensures low noise and long service life.

-

Independently adjustable left and right folding conveyors for precise box forming.

-

High-precision linear guide folding knives for accurate adjustments.

-

French Hutchinson multi-groove belt drive system included.

-

Multiple wall panel configurations for operational flexibility.

Conveyor Section

-

Asynchronous servo motor drive for stable output control.

-

Taiwan Panasonic counter and optoelectronics for batch and total counting.

-

PLC-controlled HMI ensures synchronized front and rear speeds.

-

Imported Nita flat belts and multi-groove belt drive for smooth acceleration.

-

Linear guide adjustments eliminate blind spots and improve setup speed.

-

Pneumatic counter and dual remote controllers included.

Pressing Section

-

Inverter-controlled conveyor speed synchronized with the main motor.

-

Rear air-pressure system allows independent pressure adjustment.

-

Extended rear design prevents product drop-off.

-

Electrically adjustable compression belts and auxiliary pressure belts.

-

Edge-sealing foam tape and pneumatic paper-flapping device included.

Electrical System

-

Servo-driven feeding, main drive, and output sections.

-

Integrated air-blowing and paper-flapping systems.

-

Height-limit and pneumatic leveling systems ensure stable operation.

-

Designed for efficiency and reliability under demanding industrial conditions.

Applications

The versatility of this Multi function Folder Gluer enables converters in Bangladesh to serve multiple high-margin packaging markets:

-

-

E-commerce & Logistics: Produces crash-lock bottom boxes using N, E, and F flute corrugated boards for secure shipping.

-

Export-Oriented Industries (Textile, Pharma, Food): Delivers complex cartons and tamper-evident packaging that meet global compliance standards.

-

Luxury & Electronics Packaging: Supports advanced 4- and 6-corner box production for cosmetics, electronics, and premium goods.

-

Product Comparison Table with Similar Products

| Feature | JY-1100SG Multi function Folder Gluer (Typical) | DGM SMARTFOLD 1100 SL | Benefit for Investor |

| Max Speed | 400~m/min 34 | 400~m/min 35 | Ensures optimal throughput and productivity synchronization36. |

| Corner Box Capability | 4 & 6-Corner 37 | 4 & 6-Corner (SL Model) 38 | Allows diversification into high-margin packaging39. |

| Max Blank Width | 1100~mm 40 | 1100~mm 41 | Optimal size for large logistics and main export packaging demands42. |

| Electrical Load (Estimate) | sim 22~kW 43 | 28~kW (SL Model) 44 | Lower estimated power consumption provides a marginal cost advantage against high BD tariffs45. |

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The JY-1100SG Automatic High Speed Multi Function Folder Gluer comes with a service warranty that covers technical malfunctions and performance issues related to the machine’s core folding, gluing, and high-speed processing operations. Certain wear-and-tear components—such as belts, rollers, adhesive applicators, and other consumable parts—naturally degrade with use and are therefore not included under the warranty. If any covered system experiences a functional failure within the warranty period, our technicians will provide the required repair or replacement service; however, customers must purchase any spare parts that may be needed. Please note that all shipping costs for sending or receiving parts or equipment are the responsibility of the customer.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Frequently Asked Questions

1. What defines the JY-1100SG as a Multi function Folder Gluer?

It qualifies as multi-function because it handles complex boxes, including 4- and 6-corner types, enabling higher-margin work.

2. What range of materials can this Multi function Folder Gluer process?

It processes carton board up to 800 gsm and N, E, F flutes, supporting diverse industries like textiles, pharma, and e-commerce.

3. Why is the speed of this Multi function Folder Gluer(400 m/min) necessary in the Bangladeshi market?

400 m/min is needed to match modern cutting/printing speeds, maximize productivity, and speed ROI despite high import taxes.

4. How does the JY-1100SG Automatic Multi function Folder Gluer help mitigate high energy costs in Bangladesh?

Its efficiency, consistent quality, and low waste offset its 20–28 kW load, helping manage high electricity costs.

5. Does this machine require specialized infrastructure for installation?

Yes. Its ~8-ton weight requires a strong floor and proper rigging, plus voltage stabilization and UPS due to power instability.

6. What is the expected Return on Investment (ROI) benefit from this Automatic Multi function Folder Gluer?

It enables entry into premium packaging markets and can break even in 18–30 months with about 3% waste reduction.

Prominent Tec Company Information

Address: House No. 99, Lift No. 07, Rd No. 4, Block B, Banani, Dhaka-1213, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.