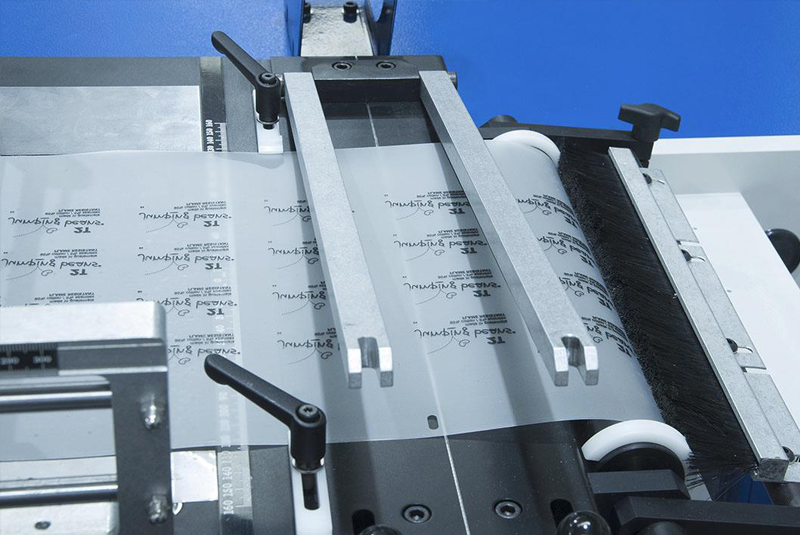

Tagtrans 225 Proscreen – High-Precision Heat Transfer Label Printing Machine

The Tagtrans 225 Proscreen is a high-performance silk screen label printing machine from Focus Label Machinery, engineered for the efficient and cost-effective production of textile heat transfers and tagless labels.

| Model name |

PT |

|---|---|

| Payment Method |

L/C at sight or T/T in advance |

| Min. Order |

01 |

| Warranty |

12 Months. |

| Packaging |

Standard Export Wooden Case |

Tagtrans 225 Proscreen

Designed for high-volume environments, the Tagtrans 225 Proscreen excels in delivering multi-colour, high-definition, and wash-resistant transfers with precise registration and minimal waste. Ideal for the demanding apparel and textile industry in Bangladesh, this advanced Tagtrans 225 Proscreen machine supports professional label printing applications and ensures superior, high-quality results for sportswear, underwear, and other skin-contact garments, while maintaining compliance with international standards.

Product Specification

| Drive System | Sevo Technology, PLC Programmable |

| Print System | Silk Screen |

| Print Length | 350mm, PLC Programmable |

| Print Width | 250mm |

| Print Heads | 270mm |

| Max Speed | 12Mts/min |

| Average Speed | 10Mts/min |

| Second Pass/Auto Register | Yes |

| Photo Eye Registration | Yes |

| Hole Punch Registration | Yes |

| Powder Adhesive Application | Yes |

| Adhesive Auto Recycle | Yes |

| Drying System | Yes, IR Drying with Recirculation Fans |

| Drying Length | Variable,12Mts to 25Mts |

| Auto Temp Control | Yes, Programmable Thermostatically Controlled |

| Cooling System | Yes |

| Auto Unwind | Yes |

| Splice Table | Yes |

| Rewind | 1 or 2, 2nd Rewind Option |

| Slitting | Yes(Knives supplied) |

| Substrates | Paper or Film, Pre-Coated (Cold or Hot Peel), Details on Request |

| Adhesive | Power, Details on Request |

| Adhesive | Liquid, Silk Screen applied, Details on Request |

| Printing Inks | Water/Solvent, Detail on Request |

Advantage & Features

The Tagtrans 225 Proscreen is a powerful solution for high-volume textile label printing in Bangladesh, offering:

-

Superior Print Quality: Delivers multi-colour, high-definition, halo-free transfers. The Tagtrans 225 Proscreen produces sharp, clean images with a tactile finish that stands apart from flat digital prints.

-

High Production Capacity: A large print area with fast thermo-controlled drying (up to 12m/min) in an integrated curing oven ensures efficient mass production. An optional twin-belt configuration on the Tagtrans 225 Proscreen can further increase throughput.

-

Exceptional Precision & Minimal Waste: Servo drives ensure accurate registration, reducing misprints and material waste while supporting cost efficiency and sustainability.

-

Cost-Effectiveness: Enables economical, high-output heat transfer production with strong ROI.

-

Durability & Wash Resistance: Transfers produced by the Tagtrans 225 Proscreen remain intact after repeated washing, maintaining label clarity and garment quality.

-

Safety & Compliance: Compatible with OEKO-TEX® and GOTS-compliant inks, meeting international safety and environmental requirements.

-

Versatility: Supports screen, rotary, or hybrid printing for diverse label designs.

-

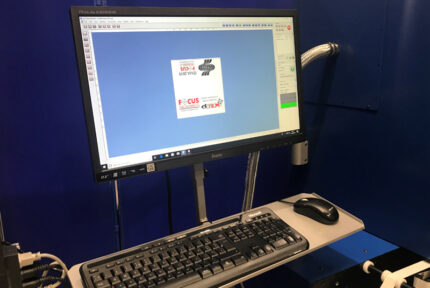

User-Friendly Operation: PLC-controlled interface simplifies operation and setup.

-

Reliable Performance: Manufactured by Focus Label Machinery, known for durable and dependable equipment.

Applications

The Tagtrans 225 Proscreen is highly versatile and essential for Bangladesh’s garment industry, supporting a wide range of textile labeling applications:

-

Tagless Labels: Heat transfer labels applied directly to garments, ideal for:

-

Sportswear

-

Underwear & Lingerie

-

Baby & Children’s Clothing

-

T-shirts & Casual Wear

-

-

Decorative Heat Transfers:

-

Brand logos and emblems

-

Multi-colour graphic designs

-

Apparel enhancements with texture and visual effects

-

-

Care & Content Labels: Durable wash-care and fabric information printed directly onto garments

-

Size Labels: Clear, permanent sizing without sewn tags

-

General Garment Manufacturing: High-volume, in-house label production using the Tagtrans 225 Proscreen, reducing reliance on external suppliers—ideal for RMG operations upgrading from tagtrans 150 technology

Product Comparison Table with Similar Products

| Feature/Metric | Tagtrans 225 Proscreen (Focus Label Machinery) | Typical Chinese Silk Screen Textile Label Printer (e.g., Ruian Jingda, Minghui) | Traditional Sew-In Label Weaving/Printing Machine (e.g., Local Manufacturers, Imported) | Digital Textile Label Printer (e.g., Inkjet-based) |

| Printing Method | Silk Screen (Heat Transfer) | Silk Screen (often heat transfer or direct fabric) | Woven or Flexographic/Rotary Screen on Fabric | Inkjet (Direct-to-Fabric or Transfer) |

| Primary Output | Tagless labels, high-definition heat transfers, decorative branding | Heat transfers, fabric labels, ribbon printing | Woven labels, printed fabric labels (care labels, brand labels) | Short-run, variable data labels, vivid graphics on fabric |

| Volume Capability | High-volume (designed for mass production) | Medium to High (varies by model) | High-volume (especially for woven) | Low to Medium (faster for variable data) |

| Print Quality/Detail | High-definition, “halo-free”, excellent colour opacity, wash-resistant | Good to High, can vary. May require careful ink management for halo-free results. | Excellent for woven details, good for flexo/rotary; limited intricate graphic fidelity. | Excellent for complex graphics, vibrant colours, fine details. |

| Wash Resistance | Excellent (designed for garment longevity) | Good to Excellent (depends on ink and curing) | Excellent (inherent to fabric/printing method) | Good (depends on ink formulation and curing) |

| Comfort on Skin | Superior (tagless, smooth feel, eliminates irritation) | Good (for heat transfers) | Can be irritating (sewn-in edges, coarser materials) | Good (if direct-to-fabric, soft hand feel) |

| Waste Reduction | Significant (servo registration, minimal material waste) | Moderate to Good (registration can be less precise) | Moderate (material waste during weaving/cutting) | Lower waste for short runs, higher for setup. |

| Ink Compatibility | Water and solvent-based, safety compliant (e.g., OEKO-TEX aligned) | Varies, often water/solvent based | Specific to weaving dyes or flexo/rotary inks | Specialized digital inks (pigment, reactive, acid, disperse) |

| Ease of Operation | Good (PLC programmable controls) | Varies, some may have simpler controls | Requires skilled operators for setup and maintenance. | Requires technical expertise for colour management and RIP software. |

| Initial Investment | Moderate to High (premium industrial machine) | Low to Moderate (more affordable options available) | Moderate to High (for industrial weaving/flexo) | High (for industrial digital textile printers) |

| Running Costs | Cost-effective per label for high volumes, efficient ink use, low waste | Can be cost-effective, but potential for higher waste. | Moderate to High (thread/fabric costs, energy) | Moderate to High (ink costs can be significant, especially for full colour) |

| Local Support (BD) | Likely via Focus Garment Tech Pte Ltd Dhaka (confirmed regional presence) | Varies widely, may have local agents or direct import support | Well-established local support networks | Growing, but may require specialized technicians |

| Compliance Readiness | High (produces labels compliant with OEKO-TEX, GOTS standards) | Varies; often possible but may require specific ink sourcing and process validation. | Generally compliant depending on materials/dyes. | High (with appropriate inks and post-treatment) |

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The Tagtrans 225 Proscreen comes with a service warranty that covers technical assistance and labor for operational malfunctions under normal use. Some items—like heating pads, silicone sheets, and other wearable components—naturally wear out over time and are considered consumables, so they aren’t covered under the warranty. If any covered part stops working during the warranty period, our technicians will handle the repair or replacement, but customers will need to purchase any necessary spare parts. Please note that customers are responsible for all shipping costs when sending or receiving parts or equipment.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Frequently Asked Questions

Q1: What exactly is the Tagtrans 225 Proscreen, and what sets it apart for textile labeling?

A1: It’s a high-quality silk screen printer that produces sharp, multi-colour, halo-free heat transfers and tagless labels with great precision and durability.

Q2: How does the Tagtrans 225 Proscreen cater to the demand for high-volume textile label production?

A2: Its large print area, 12m/min drying, and servo controls enable fast, continuous large-scale production.

Q3: Is the Tagtrans 225 Proscreen machine capable of producing labels that meet international compliance standards?

A3: Yes, it uses compliant inks, meeting global safety and sustainability standards, essential for the production of heat transfers.

Q4: Is local service and support available for this Tagtrans 225 Proscreen?

A4: Yes, Prominent Tec in Bangladesh offers installation, training, service, and spare parts.

Prominent Tec Company Information

Address: House No. 99, Lift No. 07, Rd No. 4, Block B, Banani, Dhaka-1213, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.